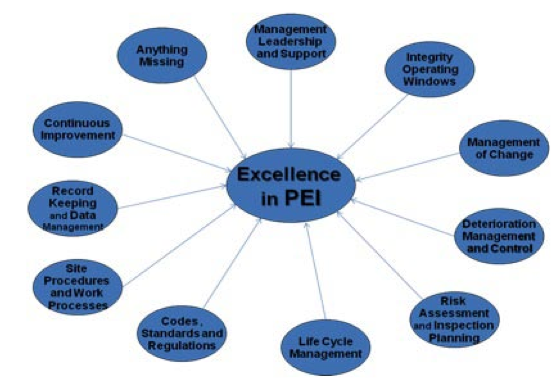

Integrity Operating Windows (IOWs) are sets of limits used to determine the different variables that could affect the integrity and reliability of a process unit. Put simply, IOWs are the limits under which a machine can operate safely. Working outside of IOWs may cause otherwise preventable damage or failure. For this reason, it's incredibly important to be aware of the IOWs for each machine that is in operation.

A common example of things IOWs can include is temperature limits on furnaces. Since leaving furnaces too hot can cause ruptures or damage to the metal, upper limits need to be set on the temperatures it’s allowed to work at. If the temperature is exceeded, then an operator should be given a certain amount of time to get it back under the limit.

It is important to develop limits for every possible damage mechanism that is likely to affect a component. This way the working within the limits for the machine will be able to prevent most likely types of damage that might affect it.

To start with, for every piece of equipment, an IOW plan should be created. A proper IOW plan will contain information for operators and others on how to respond to IOW alarms and variances along with how quickly they need to respond. It will need describe what process monitoring techniques and process sampling will be needed to provide assurance that the process stays within the established IOW limits.

API RP 584, Integrity Operating Windows (IOWs), is a standard by the American Petroleum Institute which covers IOWs and related topics. This standard deals with the parameters that should be established and the data required in order to set up a proper IOW plan. It talks about the different types of IOWs used for process units. It covers risk ranking, documenting, implementing, reviewing, changing, and updating IOWs.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition