Hydrostatic (Hydro) Testing is a process where components such as piping systems, gas cylinders, boilers, and pressure vessels are tested for strength and leaks. Hydrostatic tests are often required after shutdowns and repairs in order to validate that equipment will operate under desired conditions once returned to service.

Furthermore, hydrostatic testing cannot be performed during normal operations and cannot monitor equipment for leaks after the test has been performed. On-stream equipment integrity is best managed by an effective fixed equipment mechanical integrity program.

Although hydrostatic testing is considered to be a nondestructive testing method, equipment can rupture and fail if the inspection exceeds a specified test pressure or if a small crack propagates rapidly.

How Does Hydrostatic Testing Work?

Hydrostatic testing is a type of pressure test that works by completely filling the component with water, removing the air contained within the unit, and pressurizing the system up to 1.5 times the design pressure limit the of the unit. The pressure is then held for a specific amount of time to visually inspect the system for leaks. Visual inspection can be enhanced by applying either tracer or fluorescent dyes to the liquid to determine where cracks and leaks are originating.

Common Hydrostatic Testing Methods

There are three common hydrostatic testing techniques that are used to test small pressure vessels and cylinders: the water jacket method, the direct expansion method, and the proof pressure testing method.

Water Jacket Method

In order to conduct a this method, the the vessel is filled with water and loaded it into a sealed chamber (called the test jacket) which is also filled with water. The vessel is then pressurized inside the test jacket for a specified amount of time. This causes the vessel to expand within the test jacket, which results in water being forced out into a glass tube that measures the total expansion. Once the total expansion is recorded, the vessel is depressurized and shrinks to its approximate original size. As the vessel deflates, water flows back into the test jacket.

Sometimes, the vessel does not return to its original size. This second size value is called permanent expansion. The difference between the total expansion and permanent expansion determines whether or not the vessel is fit-for service. Typically the higher the percent expansion, the more likely the vessel will be decommissioned.

Direct Expansion Method

The direct expansion method involves filling a vessel or cylinder with a specified amount of water, pressurizing the system, and measuring the amount of water that is expelled once the pressure is released. The permanent expansion and the total expansion values are determined by recording the amount of water forced into the vessel, the test pressure, and amount of water expelled from the vessel.

Proof Pressure Method

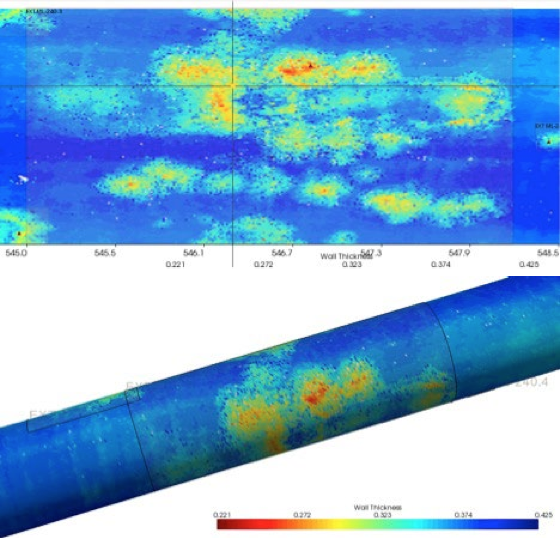

The proof pressure test applies an internal pressure and determine if the vessel contains any leaks or other weakness such as wall thinning that may result in failure. In the United States, this method is only permitted when the U.S. Code of Federal Regulations does not require permanent and total expansion values to be recorded.

Alternative Methods

Some equipment may not be designed to handle the loads required for a pressure test. In these cases, alternative methods such as pneumatic testing should be employed. Pneumatic testing is another type of pressure test that involves pressurizing the vessel with a gas such as air or nitrogen instead of water. However, special caution should be used when performing pneumatic testing as gaseous mediums have the ability to be compressed and contained in larger amounts compared to hydrostatic testing.

Notes on Hydrostatic Testing

For pipelines, hydro tests are conducted while the pipeline is out of service. All oil and/or natural gas is typically vented off, and the line is mechanically cleaned prior to testing.

In any case, operators and inspectors should consider the properties of the hydrotest fluid medium and how the medium may have an effect on the equipment. For example, water is a good environment for corrosion to take place. Therefore, equipment should be properly dried and contaminant free before starting operations.

References

- Handbook of Compressed Gases, Compressed Gas Association, Inc., 3rd Edition, pp. 184, 1990.

Related Topics

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition