| Date | January/February 2013 |

| Volume | 19 |

| Issue | 1 |

| Return to Journal Index | |

January/February 2013 Inspectioneering Journal Article Index

In response to reader feedback, we implemented some important improvements in 2012. As we broaden our scope to include all aspects of Asset Integrity Management, its synergy and leverage become increasingly important. We will sustain this forward...

This article is the third of a series of articles that will focus on one critical sub process within a PEIP that is key in managing the integrity of process piping: thickness monitoring programs for internal corrosion. These articles will discuss...

A new API Individual Certification Program (ICP) will be offered soon to certify inspectors who perform quality assurance (QA) surveillance and inspection activities on new materials and equipment for the energy and chemical (E&C) industry. It is...

In this article you will find the failure investigations of six 0.094 inch thick carbon steel vessels. These vessels were in service in natural gas well facilities; some functioned as dryers and were subjected to cyclic loads. Metallographic tests,...

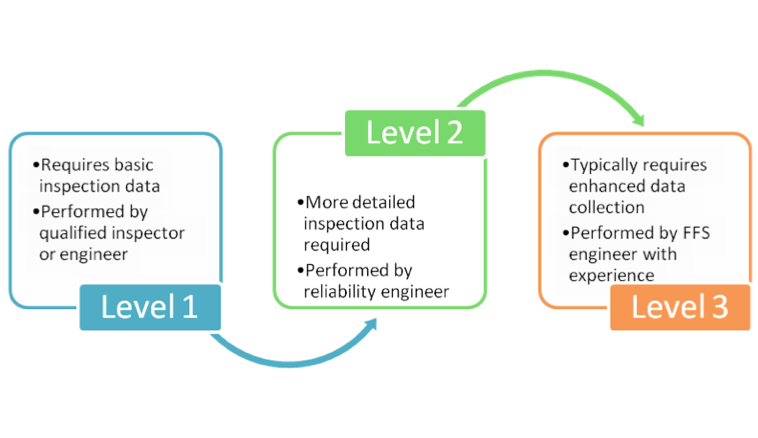

The benefits of adding fitness-for-service (FFS) assessments to energy sector reliability projects are numerous. The acceptance of API 579/ASME FFS-1 is increasing across the energy sector and other industries, as these benefits have been...