Other Mechanisms

High Temperature Hydrogen Attack

Some processes, such as hydrotreaters, utilize hydrogen gas at relatively high temperatures and pressures. The hydrotreating process temperatures promote hydrogen dissociation. Diffusing hydrogen atoms can affect ferritic steel welds and parent metal (carbon steel and low-alloy Cr-Mo steels), especially when they combine with unstable carbides that are typically created during the fabrication process.

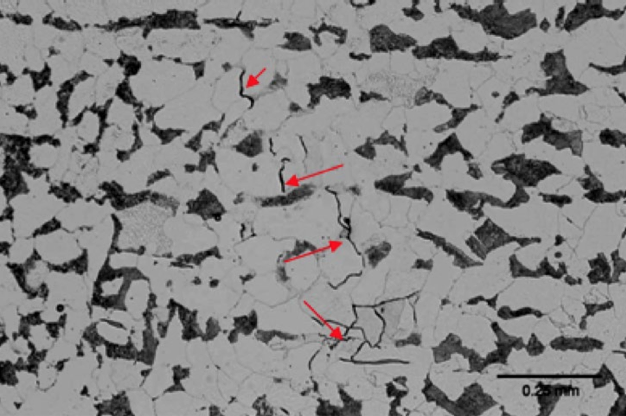

The rate of dissociation is very slow, and its effects can be ignored, at temperatures less than about 400°F (205°C). At elevated temperatures, dissolved hydrogen atoms react with local iron carbides to form methane gas (CH4); as the methane concentration and pressure increases, cracks are generated (usually in the grain boundaries). While the cracking reaction is very slow, it will eventually result in significant degradation of structural integrity.

HTHA mitigation measures include:

- In some processes, austenitic steels (e.g., 300-series stainless) are used. The chromium carbides in these alloys do not significantly react with diffusing hydrogen.

- If the pressure containing envelope is carbon or a low-alloy Cr-Mo steel, a 300-series stainless steel internal overlay or cladding may help prevent HTHA from occurring in the envelope. Note that hydrogen embrittlement may still be of concern.

- For carbon and low-alloy Cr-Mo steel envelopes, post-weld heat treatment is required (regardless of Code requirements).

Image Gallery

Titanium Hydriding

Titanium (Ti) hydriding is a somewhat unusual metallurgical degradation phenomena that can result in brittle fracture. Unlike many other steel embrittlement phenomena, this one most often occurs in thin wall Ti tubes that have been selected for their superior corrosion resistance of overhead condensers.

In certain pH ranges and under some galvanic corrosion conditions above 165 F (75 C), hydrogen penetrates the Ti tube and reacts to form an embrittling hydride phase. It can also occur when iron has contaminated the surface of the titanium tube, promoting a galvanic couple that drives hydrogen into the Ti tube.

Fabrication and repair cleanliness are vital to the avoidance of titanium hydriding. The hydriding reaction may continue until there is a complete loss of ductility, and any form of transient stress can fracture the tubes. Those stresses may occur from upset process conditions or during bundle removal or repairs.