Introduction

Decades ago, process-equipment refractory materials were considered to be inexpensive, concrete-based material. Facility managers did not spend too much time nor expense when determining what materials should be used and how those materials should be installed. Since that time, crude oil prices have increased and the associated costs of running refinery and chemical processing units have also considerably increased. Now, facility operators consider refractory issues to be extremely important and impactful on the run time of refining and chemical processing units.

As a result, refractory materials have significantly evolved during the past 15 years, testing technology is much more sophisticated, and the need for test technicians to be properly trained and experienced to use that technology is much more important than it has been in the past. Today, operators know that to ensure at least five to six year run times on processing units, production baffle testing and material prequalification and inspection processes and results are absolutely critical.

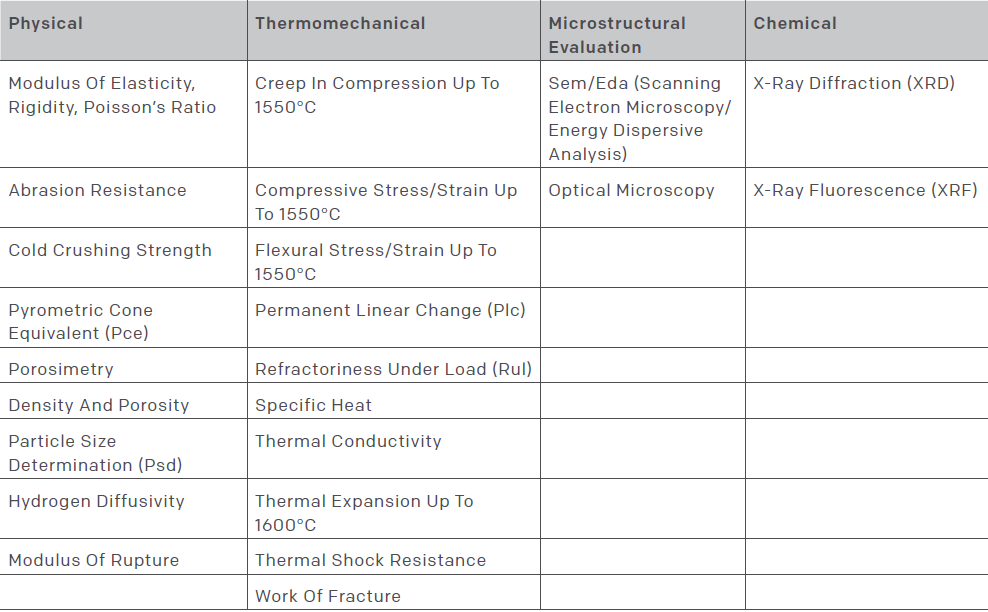

As a first step, prequalification samples are taken to ensure the materials meet the manufacturers’ specifications. How the materials should be tested is determined by ASTM Standards. The tests are conducted for a variety of reasons, including quality assurance and quality control, failure analyses, and for documentation into databases. A list of major industry-specific testing methods, for both pre- and post-installation, are included in Table 1.

What, When, Where, and Who

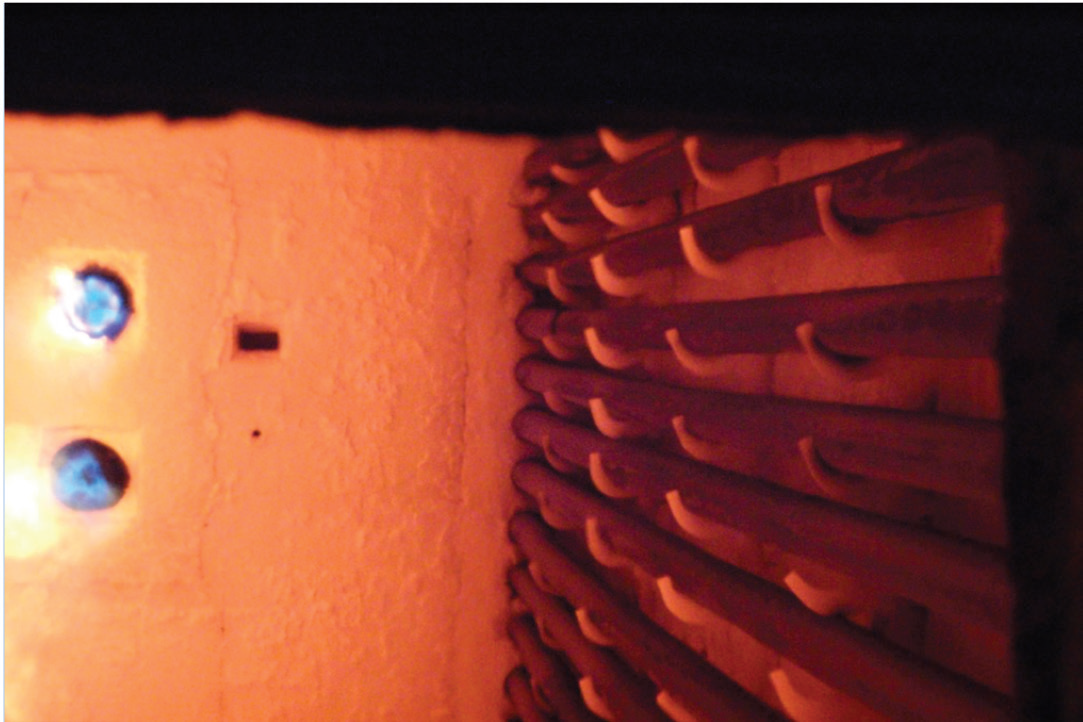

Refractory materials that are typically inspected are those used inside catalytic cracking units and cyclones where high levels of abrasion are common, among other (see Figure 1). These types of processes are critical to operational run times. Specific materials such as AA-22 and Kaolite-2200 must be inspected and tested as often as they can be, whether that is for maintenance shut down or during a major turnaround. The materials must be tested to ASTM standards and other codes, and the scheduling of refractory inspections can vary greatly. Some units that contain refractory material can be inspected whenever those units are scheduled for routine maintenance procedures, which can range from two- to five-year intervals. During these shutdowns, refractory inspectors must be on site.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.