Redirected from Intelligent Pigging

Pigging is an in-line inspection (ILI) technique in which devices referred to “pigs” are inserted into pipelines to perform cleaning and inspection activities. Pigging can be conducted on a variety of pipelines sizes without having to stop the flow of material through the line.

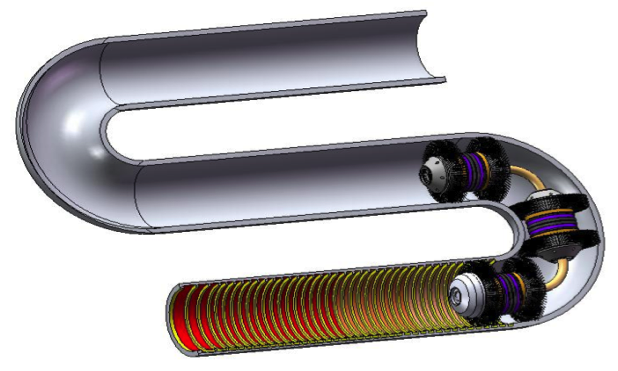

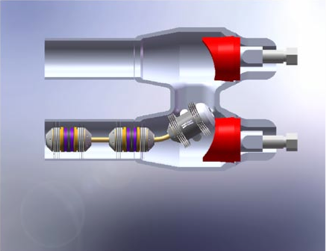

A pig is placed into the pipeline at a valve or pump station that has a special configuration of valves and pipes where the tool can be loaded into a receiver. Once the receiver is closed and sealed, the pig is then driven down the line, either being pulled through by a cable or being pushed through by the flow of product.

Traditionally, pigging was used purely as a way to clean pipelines. The pig was simply placed in one end of a pipeline and pushed through the line by the product flow. It scrapes the sides of the pipe as it travels, removing dirt and debris as it goes.

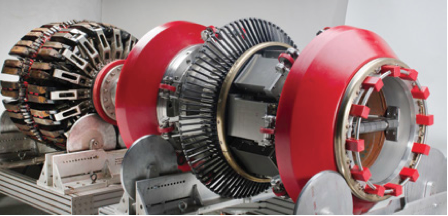

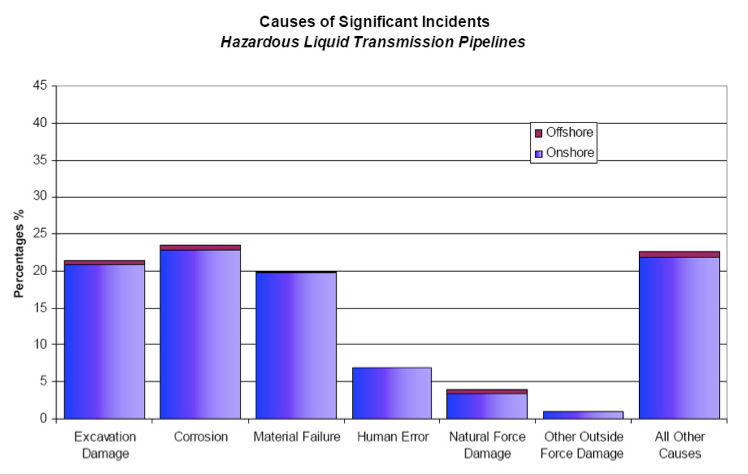

For inspection, pigs can be fitted with various nondestructive examination technologies that can scan the pipe through which it travels. These are often referred to as "smart pigs." There are several different types of smart pigs utilized in ILI activities, each with its own set of advantages and disadvantages. Some are more effective at detecting certain types of corrosion or damage in different types of pipes, depending on their NDE capabilities. More recently though, some manufacturers are combining the various functions of these separate tools into one. This way a single tool can now be used to detect several different types of damage, making it more efficient and effective.

Intelligent ("Smart") Pigging

Intelligent Pigging is an inspection technique whereby an inspection probe, often referred to as a "smart" pig, is propelled through a pipeline while gathering important data, such as the presence and location of corrosion or other irregularities on the inner walls of the pipe.

What makes intelligent pigging different is that smart pigs are capable of performing advanced inspection activities as they travel along the pipe, in addition to just cleaning it. Smart pigs use nondestructive examination techniques such as ultrasonic testing and magnetic flux leakage testing to inspect for erosion corrosion, metal loss, pitting, weld anomalies, and hydrogen induced cracking, among others. They are also able to gather data on the pipeline's diameter, curvature, bends, and temperature.

Smart pigging provides a number of advantages over traditional forms of pipeline inspection. It allows pipelines to be cleaned and inspected without having to stop the flow of product. It also allows the a pipeline to be completely inspected without having to send inspectors down its entire length. Finally, it provides cleaning and inspection services at the same time, saving companies both time and money.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition