Exposure of carbon-steel equipment to wet H2S service environments can lead to various forms of attack, e.g. hydrogen blistering and hydrogen induced cracking (HIC), stress oriented hydrogen induced cracking (SOHIC) and sulfide stress cracking (SSC). Documenting equipment have been attributed oo these forms of corrosive damage.

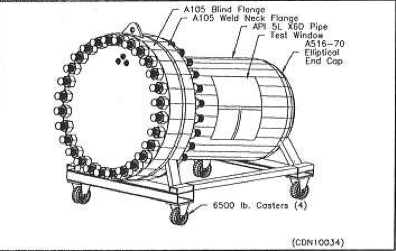

This large scale test program, sponsored by the Refining Department of the American Petroleum Institute (API) and administered by the Materials Properties Council (MPC), provided new and valuable findings on the behavior of various carbon steels and associated welds in various simulated wet H2S environments. Non-intrusive, external inspection methods, i.e., ultrasonic (UT) and acoustic emission (AE), were compared to internal wet fluorescent magnetic particle testing (WFMPT) and validated by destructive metallographic examination.

This article is the first of a two-part series which will summarize the results of this program and additional supplemental work. Part 1, presented herein, provides an examination of WFMPT techniques and shows evidence that removal of passive surface films necessary to perform WFMPT can cause increased hydrogen permeation and result in wet H2S cracking. Part 2 to be published later will summarize the UT and AE results. The results of the complete program are given in the recently released API Research Report No. 939 (Oct, 1994). Subsequent studies were conducted by CLI international, Inc. (CLI) to evaluate the application of specially formulated inhibitors to be applied following WFMPT.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.