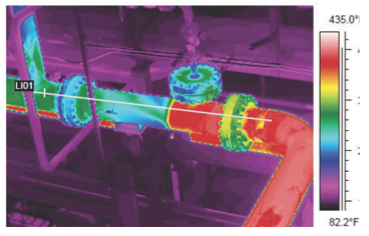

Injection Points are designated places where operators can inject chemicals into a process stream to prevent or mitigate corrosion or cracking. Different types of injectors include branch connections, quills, spargers, and spray nozzles, any of which may be used in parallel.[1] Injection points are often where two or more process streams are mixed together. For example, concentrated caustic soda into water to produce a diluted caustic soda stream. Injection points can also be used to adjust the pH of a stream by adding different chemicals to the stream.

Along with the injection point itself, there is a good deal of additional equipment that is required, including pumps to deliver the small streams, flowmeters to ensure proper flow, strainers, relief valves, check valves, associated piping, and sample points that will be accessed to measure the effectiveness of the injected material. How these should be installed depends on the individual application. Injunction points are covered under the API 570 "Piping Inspection Code" and NACE SP0114-2014 "Refinery Injection and Process Mix Points" industry standards.[1]

References

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition