| This article is part 2 of a 2-part series. |

| Part 1 | Part 2 |

Data Loggers / Recorders

Many digital ultrasonic thickness gauges have internal memory that allows the storage of thousands of thickness readings. Some instruments have “sequential” data loggers that store the thickness values in a numerical series. These data loggers are easy to use and many allow the creation of multiple files. The multiple files are typically used to separate the storage of data from different pieces of equipment or different locations.

Programmable alphanumeric data recorders are the most versatile and frequently used devices for recording thickness values. They allow computer programs to upload pre-defined file structures into the data recorder memory. Once in memory, the operator can activate a file, perform the inspection and save the readings in memory for later downloading to compatible inspection database management systems. The most powerful data recorders support adding comments and A-Scan attachments for additional documentation of any reading.

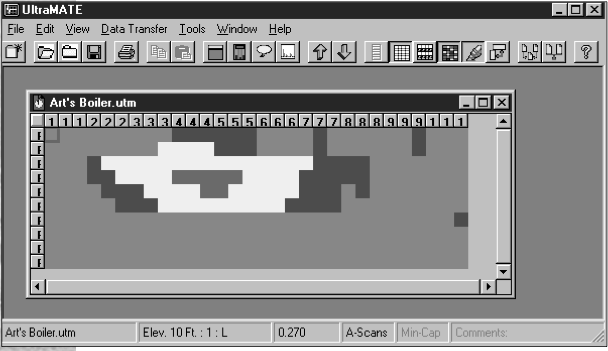

Programmable data recorders can manipulate the data into different file formats. Common data recorder file formats are linear, grid, and custom (examples shown below).

- The Linear File; is a sequential listing of values labeled through a user selected number (based upon the file length). This type of file is usually used when testing a pipe, different samples, or items that are of the same design.

- The Grid File; is a quadrant listing of values, normally starting at “A1” through a user selected range (based upon the file size needed). This type of file is used when testing an equipment item that is mapped in sections or quadrants like a tank or a plate or pipe elbow.

- The Custom File; is configurable to multiple levels. The user can enter any text value at each point of the file. Application software programs for unique identification of a test point use this file format. Programs can read the combination of label values and locate the data file or database entry and add the values into the data history.

Other file types might include features like; Custom Grid, with editable labels on both axis, Custom Point, with editable point labels and Boiler, which organizes the data to correspond with the physical attributes of the boiler tubes.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.