Storage tank owners can reap large financial benefits by shifting from a reactive tank repair strategy to a proactive inspection and maintenance program. In reaction to well publicized tank failures in the 80’s and the development of API 653 guidelines in 1991, many tank owners started to proactively inspect their tanks and perform significant tank repairs. However, after a lengthy period of focus on inspections and repairs in the 90’s, many tank owners have become complacent with respect to tank maintenance.

Many companies have been under tremendous financial pressure over the past few years, encouraging storage tank managers to defer preventive maintenance projects. In certain cases, tank maintenance activities have been substantially trimmed or eliminated in an effort to deliver short term cost reductions. However, deferring inspection and repair activities has increased the risk of tank failure as well as the potential financial implications from remediation requirements.

A deficient tank management program also puts the tank owner into a reactive cycle where tank inspections are overdue, and the tank owner has only enough time and resources to handle emergency repairs. While deferring tank inspections and maintenance has provided short term benefits in the past, the cycle must now be reversed so that tank owners avoid tank failures, unusually high tank repair costs, and ultimately, an uncompetitive position relative to their peers. This paper demonstrates that by initiating a proactive tank management program, tank owners can significantly reduce their cost of operations. The story below summarizes an approach to a proactive tank management program that can be managed cost effectively, that will optimize tank repair timing and funding, and reduce environmental risks.

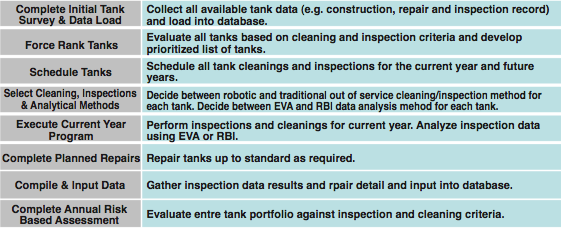

A comprehensive Tank Management Program is a cyclical process of planning and executing tank cleaning, inspection, and repairs as portrayed in Figure 1 (page 3).

Step 1: Initial Tank Survey & Data Load

The starting point in the cycle is to collect all available tank records and data for the entire tank population. For some facilities, this is an arduous process since the records are not always centrally stored nor in electronic format. Important tank documents include “as built” drawings along with construction, inspection and maintenance records. It is also important to track the tank service history, special environmental conditions, and enhancements made to the tank, e.g. cathodic protection.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.