John Brear: About the Author

ERA Technology Ltd.

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

May/June 1997 Inspectioneering Journal

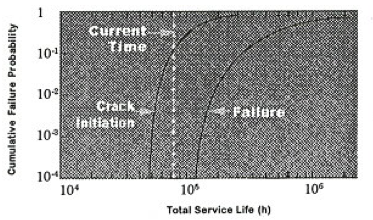

Reformer catalyst tubes are commonly manufactured from high strength, creep and corrosion resistant alloys. They are relatively thick walled and are usually produced by centrifugal casting. Their lives are limited by creep, driven by a combination...