A pair of Delayed Coker Drums was placed in service in 1968, and now have 28 years of service in what may be the most severe cyclic loading conditions of any petrochemical vessels. They are a conventional ASME VII/Div 1 pressure vessel design based on 60 psi and 836 0 F at the top and 899 0 F at the bottom. This design provides increasing thickness, from the bottom up, in seven rings constructed with clad plates, using longitudinal and circumferential weld seams.

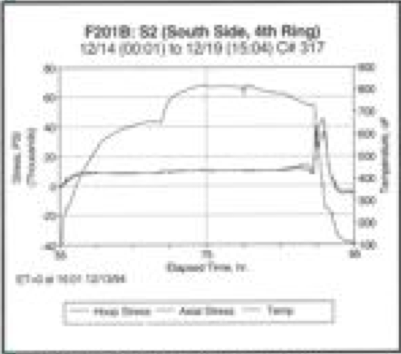

The drums were instrumented in June 1993 with 40 thermocouples and six strain gages to characterize their structural behavior for an extended recording period. The results were sufficient to justify leaving the instrumentation in place to record every cycle of operation. After the first year, the thermocouples were moved to different locations around the drum and eventually reduced to only the three strain gage locations. This performance history was an integral component of the evaluation concluded in May of 1995 resulting in the replacement of significant portions of the drums because of distortion. The instrumentation is currently monitoring the companion pair of drums.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.