The upstream oil and gas industry is cyclically faced with low oil prices and high operating costs, with the growing challenge of ageing assets and increasingly complex infrastructure. Similarly, the downstream market is struggling to maintain production uptime of ageing assets operating at maximum capacity due to increased availability of low cost feedstock and high demand for their products. Whilst safety remains paramount, improving asset reliability is just as crucial to stay competitive and to realise cost efficiencies.

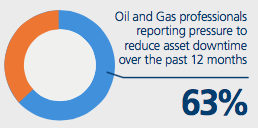

Offshore platforms pipelines, terminals and downstream facilities, are costly to build, operate and maintain, so it’s imperative that operators keep tight control over the total life-cycle cost of all associated equipment. In order to maintain operation and production, mitigating against downtime is a key objective; in a survey of oil and gas professionals, 63%1 stated that the pressure to reduce asset downtime over the past 12 months has increased. Asset management software can undoubtedly reduce costs and improve asset reliability in line with a comprehensive and effective asset performance management (APM) strategy.

In addition to the market challenges of price volatility, shareholders are pressing companies to maximise value. A strong focus on operational efficiency will remain a priority for the foreseeable future whilst operators maximise recovery. These challenges are compounded by having to do more with limited resources, skills shortages and an ageing workforce, which the Financial Times described as ‘Terrifying’ in relation to attrition and the impact on project delays and raising risks.

Asset management software tackles daily operational challenges by optimising inspection and maintenance regimes and driving efficiencies. The ARC Advisory Group highlights the key drivers for operators purchasing asset management software as uptime, cost control, asset longevity, and safety. Whilst an IDC survey cited “Process and operations optimisation and control”2 as being a driver for data management and the use of analytics.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.