Excessive equipment vibration is a common issue experienced in industrial processes and facilities. Excessive vibration is most often caused by misalignment of equipment or components, unbalanced rotating equipment, or loose components (e.g. bolts). If not addressed, prolonged vibration can result in damage to equipment and may even cause system failure. Fixed, rotating, and structural assets are all susceptible to problems caused excessive vibration.

In its simplest form, vibration is a repetitive motion of a structure and can occur in numerous forms. Various types of vibration (e.g. free vibration, forced vibration, flow-induced vibration, random vibration, etc.) can be measured for analysis. The purpose of these Vibration Analysis is to determine how equipment will respond to an applied load or external force. Vibration analysis can also be used to determine the root cause of failure.

Vibration analysis is an important element in reliability centered maintenance, condition monitoring and predictive maintenance programs. The key benefits of identifying and mitigating vibration problems include reducing the risk of failure, extending the life of equipment, and lowering overall maintenance costs.

Tools and Techniques

Several techniques exist depending on the needed level of analysis and type of equipment and risks present.

Vibration Surveying and Monitoring. Monitoring is the simplest way identify vibration problems. Inspectors will install portable vibration sensors (e.g., probes) in multiple locations to acquire data about the type and magnitude of vibrational modes. The recorded data provides information to inspectors on the severity of the problem and on what type of analysis should be performed next.

Sometimes, long-term monitoring is necessary. Vibration monitoring allows operators and inspectors to determine appropriate inspection and maintenance intervals as well as identify causal relationships between facility operating conditions and vibration problems.

Experimental Modal Analysis (EMA). EMA is type of vibration test that involves applying various loads to a sample and measuring the resulting vibration signals. The applied loads simulate what the sample would experience in operating conditions. This method provides a theoretical solution that is used to correct vibration problems or calibrate computer models. Additionally, this technique is applied when equipment is not in service.

Operational Modal Analysis (OMA). Compared to EMA, OMA is performed when background noise signals make it difficult to distinguish from actual vibration signals. OMA is also performed while equipment is in service. This method is achieved by installing vibration sensors to measure operating vibration modes and natural frequencies.

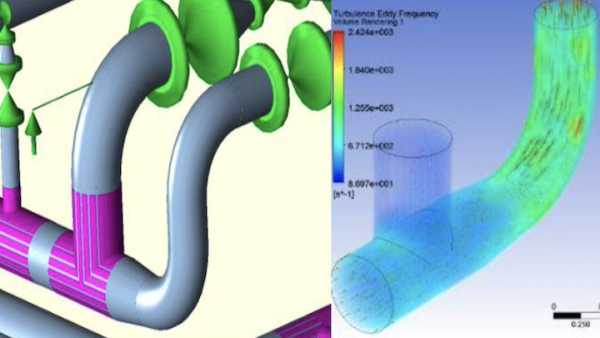

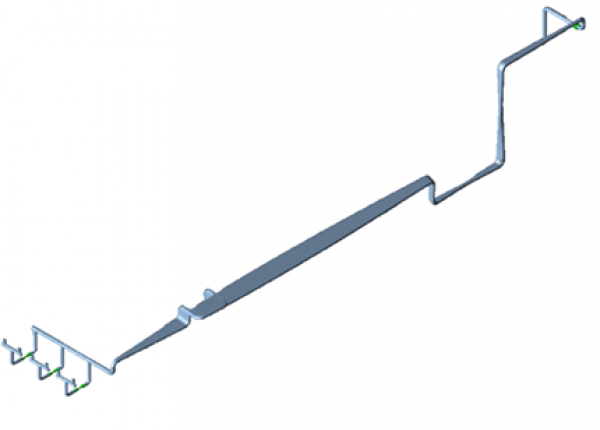

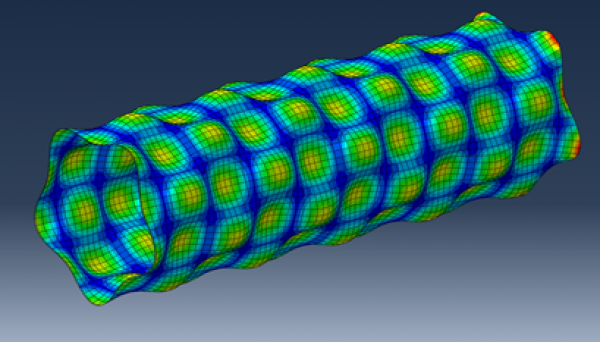

Computer Simulations. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are two common computational tools used to solve vibration problems. FEA has the ability to simulate real-world situations. Additionally, various operating conditions can be tested before the component is in service. This means that modifications can be made in a computer system rather than an actual component. CFD is also a valuable tool that simulates flow-induced vibration problems often found in a petroleum refinery or chemical processing facility.

Industry Application

Vibration analysis can be performed on all equipment that is subject to vibration problems. Piping that transports fluid, equipment that cycles between different temperatures and pressures, and rotating equipment are among the most susceptible components to experience vibration. This analysis should be performed shortly after start-ups and repairs to ensure equipment is operating within integrity operating windows.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition