Welding is the process of joining separate materials, usually metals or thermoplastics, using extreme heat. Welding is an ancient trade that has been around for thousands of years, and it is one of the most important and widely used manufacturing processes in the world.

Welding Processes

There are several types of welding processes used in the refining and petrochemical industries, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), submerged arc welding (SAW), stud welding (SW), plasma arc welding (PAW), and electrogas welding (EGW). Each process has its own set of advantages and limitations, and the choice of process depends on factors such as the materials being welded, the thickness of the materials, the required weld strength, and the environment in which the welding is being done.

Metallurgy

Metallurgy is the study of the physical and chemical behavior of metals and alloys and is an important aspect of any welding activity. The metallurgy of a welded joint will depend on the base materials being welded, the welding process being used, and the post-weld heat treatment (PWHT) applied. PWHT is the process of heating a welded component to a specific temperature for a specific period of time, followed by cooling at a controlled rate, in order to improve the mechanical properties and/or reduce residual stresses. Welding inspectors should have an understanding of the metallurgical principles involved in welding and PWHT in order to properly evaluate the quality and reliability of welded joints.

Welding Inspection

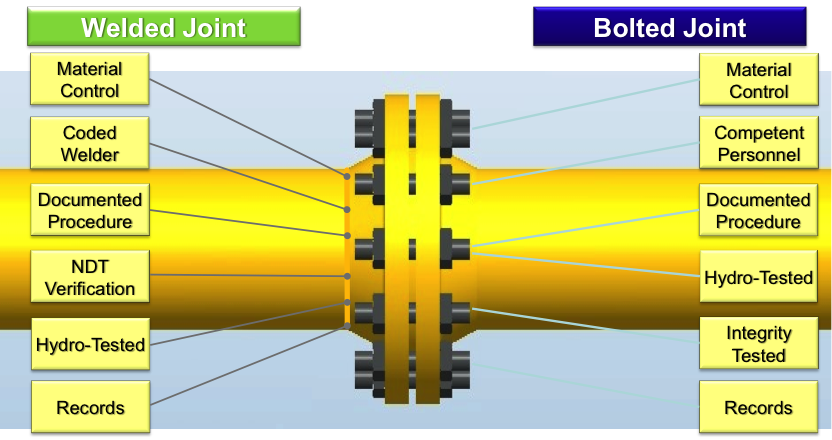

Welding inspection is the process of examining welds to ensure that they meet the required standards and specifications. This is important in the refining, chemical, and petrochemical industries because welding imperfections or defects can lead to equipment failure or leaks, which can have serious consequences such as injury, environmental damage, and financial loss. Welding inspection is typically carried out by trained professionals who use a variety of methods and techniques to evaluate the quality of welds.

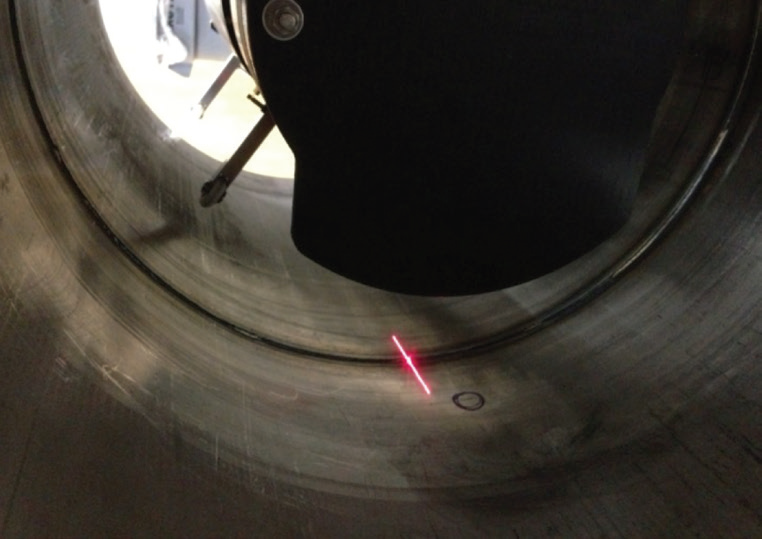

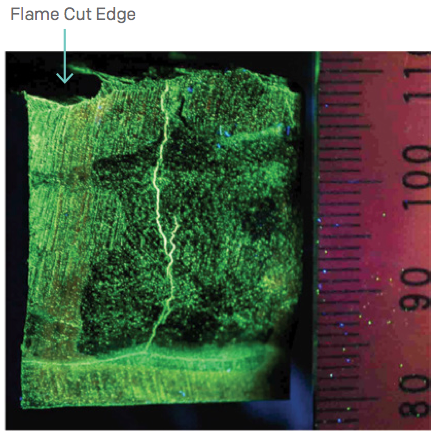

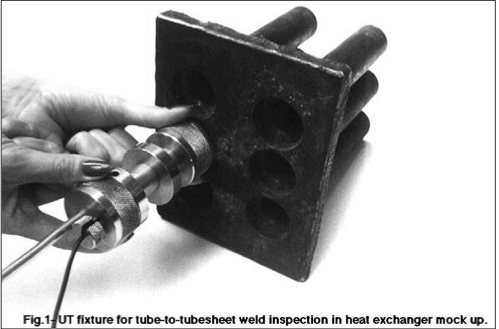

Welding inspection activities can be performed visually, using non-destructive testing (NDT) methods, or through destructive testing methods. Visual inspection involves examining the surface of the weld for defects such as cracks or incomplete fusion. NDT methods, such as radiography or ultrasonic testing, can be used to detect internal defects in the weld. Destructive testing involves physically testing the weld by applying force to it until it fails, to determine its strength and quality.

Relevant Codes & Standards

There are several codes and standards that provide guidance on welding inspection in the refining and petrochemical industries, including:

- American Petroleum Institute's Recommended Practice 577, Welding Processes, Inspection, and Metallurgy. This practice provides guidance on the selection of welding processes, inspection methods, and metallurgical principles for welding in these industries.

- American Welding Society's D1.1 Structural Welding Code. This code provides guidelines for the design, fabrication, and inspection of welded structures.

- American Society for Testing and Materials' Standard Specification for Fusion Welding for Aerospace Applications. This standard provides requirements for fusion welding of aerospace applications.

References

- https://inspectioneering.com/feature/mipi/wi/intro

- API RP 577, Welding Processes, Inspection, and Metallurgy

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition