Steam reforming is a process in which hydrocarbon feedstocks are converted into synthesis gas that contains hydrogen and carbon monoxide. The steam reforming process works by reacting high temperature steam with a hydrocarbon. Natural gas is commonly used as the feedstock for the production of hydrogen but fossil fuels, such as naphtha, liquid gas, or refinery off-gas, can also be used.

The Reforming Process

Natural gas steam reforming, also known as steam methane reforming (SMR) is the most prevalent process for hydrogen generation. Natural gas contains methane, which, in the presence of a catalyst, reacts with steam that has been heated to 700°C – 1,000°C to produce synthesis gas (predominantly comprised of hydrogen and carbon monoxide). These reactions take place in what are aptly referred to as steam reformers.

A steam reformer is made up of several sections that house the different reactions. The process begins in a furnace where the feedstock is mixed with high temperature steam. The steam and natural gas mixture then moves into heated reformer tubes that contain a catalyst.

The first reaction occurs as the mixture flows through the reformer tubes. In this stage of the process, methane and steam react to produce hydrogen and carbon monoxide.

The next stage in the process is the water-gas shift reaction. Here, the carbon monoxide produced in the first stage and steam are reacted with a catalyst which creates additional hydrogen and carbon dioxide.

The final stage occurs in the pressure swing adsorber. This is where any last bits of carbon dioxide and methane are removed from the process to produce clean hydrogen.

Reformer Tubes

As previously mentioned, reformer tubes are the components of steam reformers where the initial reactions take place between the steam and hydrocarbons. A typical reformer can contain 200 to 400 vertically hanging tubes that are heated externally by gas burners.

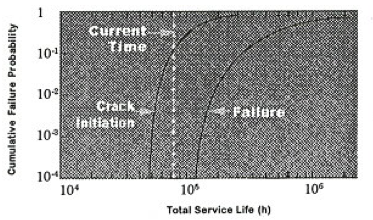

The service life of reformer tubes tends to be very limited. This is most often due to the intense stresses that reformers are put through as a part of their day to day operation. They undergo alternating thermal and mechanical stresses, carburization, and oxidation, both on the inside and outside. Reformer tubes also tend to be particularly vulnerable to creep, which can also lower their life expectancy.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition