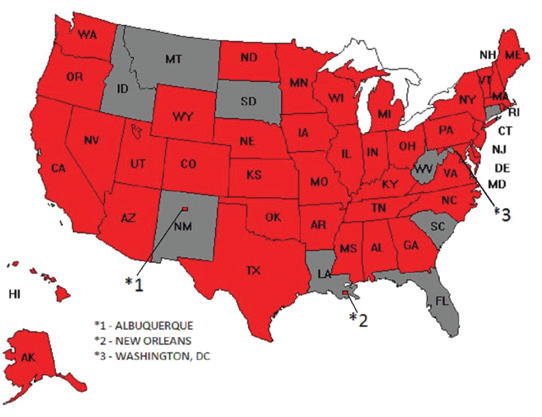

Offshore is a general term used to describe oil and gas operations that take place in the world's oceans and other large bodies of water, where some of the largest oil and gas reservoirs have been discovered. This term typically refers to exploration and production activities conducted on offshore drilling rigs, however offshore pipelines and storage facilities exist as well. Because many of the same process safety risks are present in offshore operations, it is important that operators take extensive measures to ensure the safety and reliability of their equipment.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition