A Hydrogen Bake-out is an essential, yet oftentimes undervalued procedure in petroleum refining. Under certain conditions, atomic hydrogen can diffuse into steel equipment. Hydrogen Bake-outs are used to drive this hydrogen out of the steel, as trapped hydrogen can cause cracking in a weld or an entire vessel, including delayed cracking, cold cracking, hydrogen assisted cracking, hydrogen induced cracking, or hydrogen embrittlement.

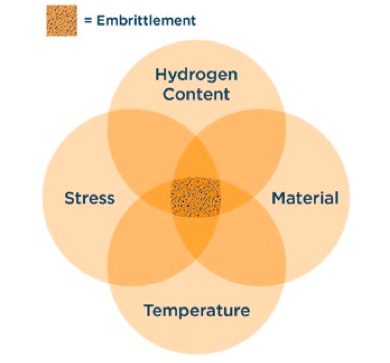

Hydrogen cracking in ferritic steels only occurs when a critical combination of four basic factors is exceeded. These factors are:

- Hydrogen content,

- Susceptible microstructure,

- Stress, and

- Temperature.

Hydrogen uptake by steel can occur at specific conditions at both low temperature as well as high temperatures. At low temperatures, atomic hydrogen forms as a result of corrosion involving hydrogen promoters, such as H2S and hydrofluoric acid (HFA), or cleaning & pickling. At high temperatures, atomic hydrogen forms as a result of welding - when wet electrodes charge the steel with hydrogen, and service at high temperatures - when a small amount of hydrogen gas can dissociate to form atomic hydrogen and diffuse into the steel.

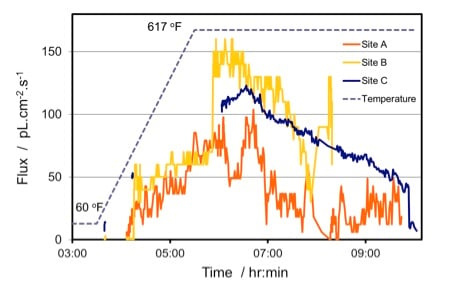

Hydrogen bake-outs involve heating the steel to an elevated temperature and allowing time for the hydrogen to diffuse out of the steel, leaving it hydrogen-free and weldable. There is some uncertainty though over the exact time and temperature needed to effectively "bake out" the hydrogen to a safe level, and there are several disagreeing opinions on the subject.

Hydrogen bake-outs should be used on all steel equipment to remove molecular hydrogen from equipment to prevent it from becoming brittle and cracking during or after welding. It cannot be overstated how important this process is before welding, as failing to do so can lead to expensive and dangerous problems.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition