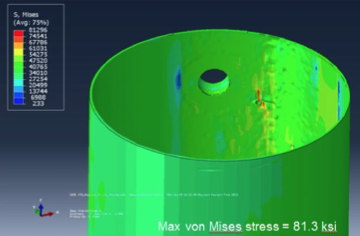

Finite Element Analysis (FEA) is a computerized system of theoretical modeling used to predict stress locations and causes of failures in different materials. This method is useful for simulating, modeling, and analyzing problems that could affect complicated systems, such as oil pipelines or oil platforms.

FEA is based on the idea that most engineering problems can be solved more easily by using mesh generation techniques to divide a component into a large number of smaller, finite elements. Each of these finite elements can then be analysed individually. The analysis works by using equations to predict the behavior of each individual object under specific conditions. These individual behaviors are then calculated together to gain an understanding of how the system will behave as a hole under the set conditions.

Some of the things that can be analysed and predicted by FEA include: the effects of stress, damage caused by contact between parts, fatigue and fractures, vibration fatigue, and damage due to fire or heat transfer. The method is particularly useful because it tends to be more accurate than other methods and can examine a complicated system with great precision. Likewise, it can be performed much more quickly than traditional hand calculations.

On the other hand though, use of computerized models has several limitations as well. They are unable to account for things such as: human error in input data, the properties of materials, and geometrical features that could possibly be missed by analysts. Likewise, there is to expected a certain amount of error in every type of numerical analysis, and FEA is no different in this regard. The degree of error in any one analysis is dependant on the type, size, and accuracy of the model used in the analysis.

FEA is covered, along with other fitness-for-service analysis techniques, under API RP 579-1 / ASME FFS-1.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition