Much of the equipment used in the refining and processing industries is known as Process Equipment. Most pieces of process equipment are designed to perform specific, singular tasks. Process equipment can be used for tasks as varied as storage, controlling flow, and containing chemical reactions.

There are two major types of process equipment: Fixed Equipment and Rotating Equipment.

Fixed equipment refers to any piece of process equipment that generally does not move. Fixed equipment is also sometimes known as static equipment and includes, but is not limited to:

- Heat Exchangers

- Piping

- Storage Tanks

- Valves

- Pressure Relieving Devices

- Boilers

- Furnaces/Heaters

- Pipelines

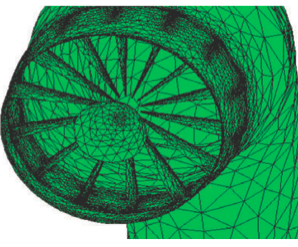

Rotating equipment generally refers to any process equipment that moves or rotates. This type of equipment is most often used to drive process fluids through a system and includes:

- turbines

- pumps

- compressors

- gearboxes

- engines

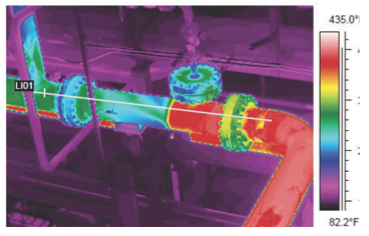

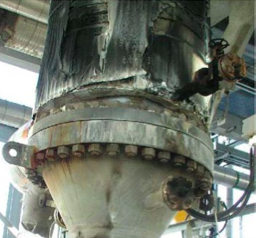

When designing process equipment, it is important to take into consideration the kind of environment in which the equipment will be operating. It’s important to design the equipment so that it resists corrosion and other damage mechanisms likely to occur in that particular environment. Likewise, proper inspection and maintenance schedules are also integral in order to ensure the continued safety and functionality of the equipment over its lifespan.

Relevant Links

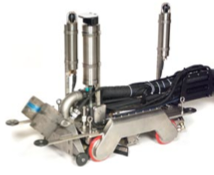

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition