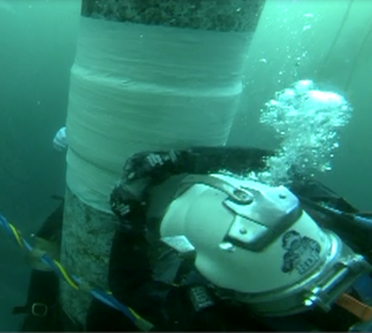

Composite Repair refers to the process of using composite materials in order to repair damaged assets. Composites can be used to temporarily repair process piping, pipelines, heat exchangers, hoses, storage tanks, and other pressure vessels.

The use of composite materials to repairs existing equipment occurs in many industries besides the oil & gas industry. These include the marine, power generation, mining, automotive, aerospace, and civil infrastructure industries.

Composite repairs are helpful alternatives to traditional maintenance practices because they can often be performed without having to shutdown the equipment. Likewise, different types of composites can be designed for use in different environments, to have different properties, and to repair different types of material.

Composite repairs are commonly examined for fitness for service using ultrasonics, radiography, holography, and thermography. X-ray and Gamma-ray inspection, while less common, are also particularly useful for composite repair inspection.

While composite repairs are useful, they aren’t perfect and the process does have flaws. Composites are often heavier, weaker, or stiffer than the original material. Because of this, they aren’t perfect for every situation. Even in situations where composite repairs are viable, they shouldn’t be counted on to last indefinitely.

This type of repair used to be considered only as a last resort, but is slowly becoming more common as a temporary repair alternative.

Relevant Links

Topic Tools

Share this Topic

Contribute to Definition

We welcome updates to this Integripedia definition from the Inspectioneering community. Click the link below to submit any recommended changes for Inspectioneering's team of editors to review.

Contribute to Definition