Introduction

Aging equipment, along with more aggressive service, makes it more important than ever to carry out fitness-for-service (FFS) assessments in support of run/repair/replace decisions. Testing material in the service-degraded condition enables quantification of the material condition and provides increased accuracy in FFS evaluations of these components. Depending on the service and material, properties of interest to a plant engineer include, but are not limited to, (a) tensile properties; (b) creep properties; (c) and fracture toughness. In addition, it is often desirable to gain an understanding of the microstructural condition of service-aged components as microstructural damage is often a precursor to catastrophic failures. While field metallographic replication (FMR) is often used in order to examine the surface microstructure of in-service components, the technique lacks the resolution needed to identify incipient damage, such as voids due to creep and/or high temperature hydrogen attack (HTHA).

Small specimen testing, which involves removal of small amounts of material that do not require post-removal repair of the component (or requiring minimal repair) and subsequent testing, is aimed at addressing this problem. Boat and scoop sampling techniques allow for minimally invasive extraction of material from in-service components. Small scale testing may also be beneficial in cases where the objective is to characterize distinct microstructural regions, such as the heat-affected zone (HAZ), in a weldment. However, the small amount of material that is available at one’s disposal necessitates the adoption of novel specimen geometries and test procedures, which can be more effective than existing standard methods in evaluating the specific material parameters needed in FFS studies. A number of such specimens and tests for measuring short-term mechanical, long-term creep, and fracture properties will be described in this article.

Scoop Sampling

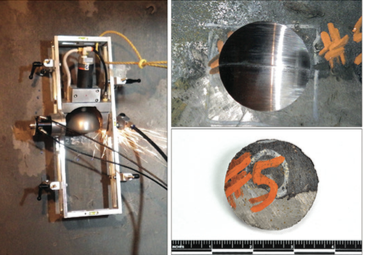

Scoop sampling refers to the removal of lens-shaped samples from a component for additional testing. Typically, this involves pressure-containing equipment in the context of refining and petrochemical industry. This sampling technique leaves behind a relatively smooth surface that requires minimal or no repair, as long as the minimum wall thickness requirement is not violated, or the local thin area (LTA) left behind is deemed fit for service. Scoop sampling has been around since late 1980’s, but has gained wider acceptance in the industry only within the last few years with advances in technology allowing for increased availability, portability, and faster cutting speeds. Figure 1 shows a scoop sampler removing material from the ID surface of a pressure vessel, as well as the sample that was removed, and the vessel wall after removal showing the concave depression left behind. The smooth contour of the scooped region requires minimal buffing, if any, to avoid geometric stress raisers. A pneumatically powered and cooled scoop cutter allows for a cutting time of about 20 minutes, while at the same time increases the life of the cutting blades. Samples can be extracted with depths of over 1”, and 4” in diameter depending on the minimum wall requirements.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.