| Date | May/June 2015 |

| Volume | 21 |

| Issue | 3 |

| Return to Journal Index | |

May/June 2015 Inspectioneering Journal Article Index

Pipeline integrity is critical to ensure maintenance and operational efficiency; however it is becoming an increasingly challenging task for the energy industry. Maintenance managers and inspectors must make sure their pipeline(s) and its associated...

In recent years, the growing use of composite repair systems for the rehabilitation of piping systems in the refining and chemical industries has increased the need for associated technologies for their manufacturing, installation, and inspection....

Historically, regulations regarding dent severity have been governed by one of two metrics: dent depth or strain. In the case of the former, plain dents with a depth up to 6% of the nominal diameter are permitted in both gas and liquid pipelines....

For traditional in-line inspection (ILI) vendors, considering 21.4 miles of a piggable 4” diesel pipeline is typically not a big deal. However, significant threats like 3rd party damage and external corrosion seem to come with the territory in...

Verifying pipeline integrity is particularly challenging due to the difficulty of pipeline access, as well as the limitations in available technology to perform subsea wall thickness inspections. These challenges require action rather than reaction.

TEAM provides full inline, onsite and, shop valve repair services and maintenance programs for virtually all valve types, brands, sizes, materials, pressures, and operating conditions, including actuators and operators. Our valve repair solution...

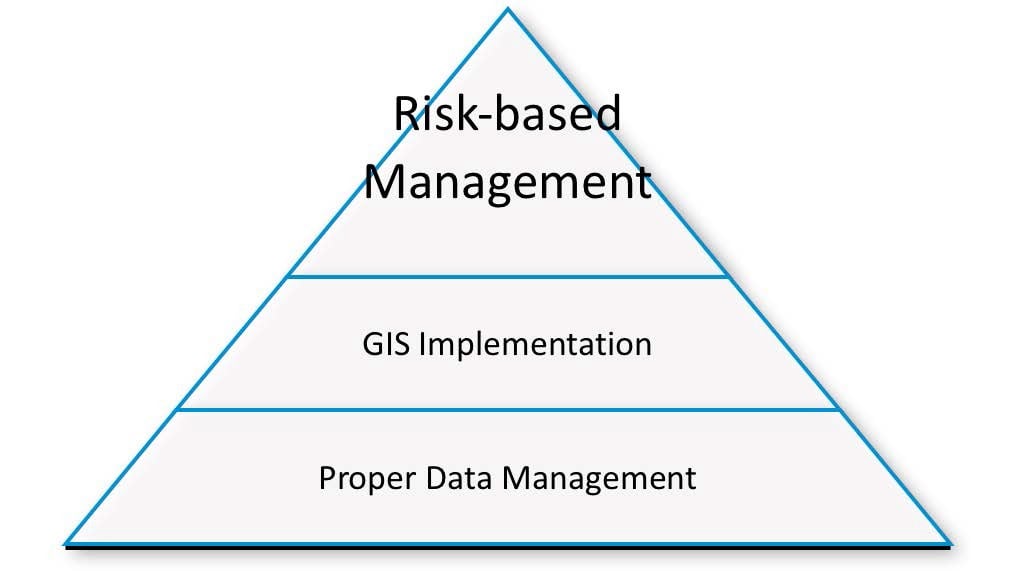

Assessing risk is an integral part of working at a refinery. Infrastructure supporting the miles of piping, process vessels, and the platforms and ladders used in daily unit operations are often taken for granted. The Civil Structures Management...

Machine-to-Machine connectivity combined with advanced computing capabilities and industry-focused software enable a wide range of new capabilities. From smart homes controlled over the internet, to smart electric grids with smart meters, sensors...

While performing visual inspections with a pen and notepad is the traditional way to record data, there are now more efficient ways to complete inspections out in the field. Investing in a mobile inspection application can be a great way to save...