| Date | March/April 2015 |

| Volume | 21 |

| Issue | 2 |

| Return to Journal Index | |

March/April 2015 Inspectioneering Journal Article Index

Today, many managers are finding that they can address the reliability of all types of assets by combining RBI and Reliability Centered Maintenance (RCM) processes together into one comprehensive reliability management process.

With the advancements in today’s technology and improvements to Enterprise Asset Management (EAM) systems and Computerized Maintenance Management Systems (CMMS), if we deploy them properly and in line with best practices, it is possible to reach...

The tubes of heat exchangers (HX), whether for a shell and tube bundle or an airfin, are typically subject to some form of nondestructive examination (NDE) to try and quantify the remaining wall thicknesses and corrosion rates to help a plant to...

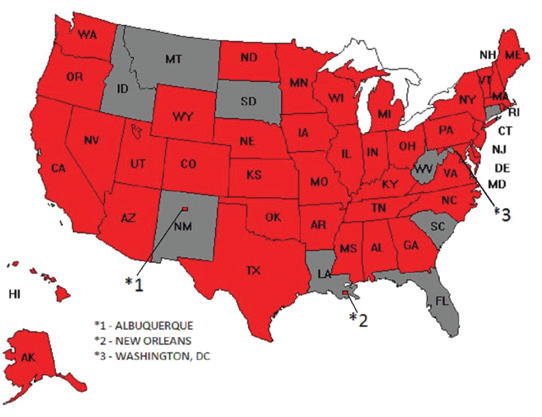

This article provides a discussion of a recent inspection performed at a U.S. refinery. Industry HF lines are experiencing piping failures in increasing numbers due to the presence of residual elements entrained within their carbon steel components.

An issue that arises frequently in the oil and gas industry is poor or missing documentation of pressure vessels. It is common in the industry to repurpose old equipment, bring equipment back into operation after a long period of time out of...

Our proprietary furnace tube inspection system, FTIS is an ultrasonic inspection technology capable of rapid, automated fired heater coil inspection in refinery fired heaters. The data captured by our furnace tube inspection system is...

Rope access allows for a wide variety of work to be performed at high elevations or other hard to reach areas without the use of scaffolding or heavy equipment. It has evolved from techniques used in rock climbing and caving to become an extremely...

Refractory materials have significantly evolved during the past 15 years, testing technology is much more sophisticated, and the need for test technicians to be properly trained and experienced to use that technology is much more important than it...

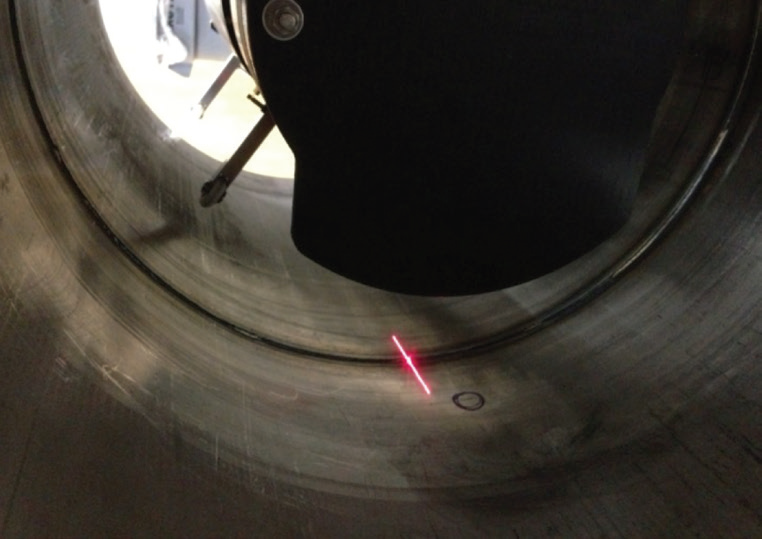

Weld inspection using lasers is not new, but doing it 75 meters inside a pipe or streaming inspection data wirelessly is new. As laser technology has improved, more industries such as oil & gas are beginning to require laser inspection as part of...

The ability to gain this unique perspective has recently become easier and safer with today’s technological advancements. This new technology comes in the form of a miniature flying machine, better known as a drone or small Unmanned Aerial System...