Introduction

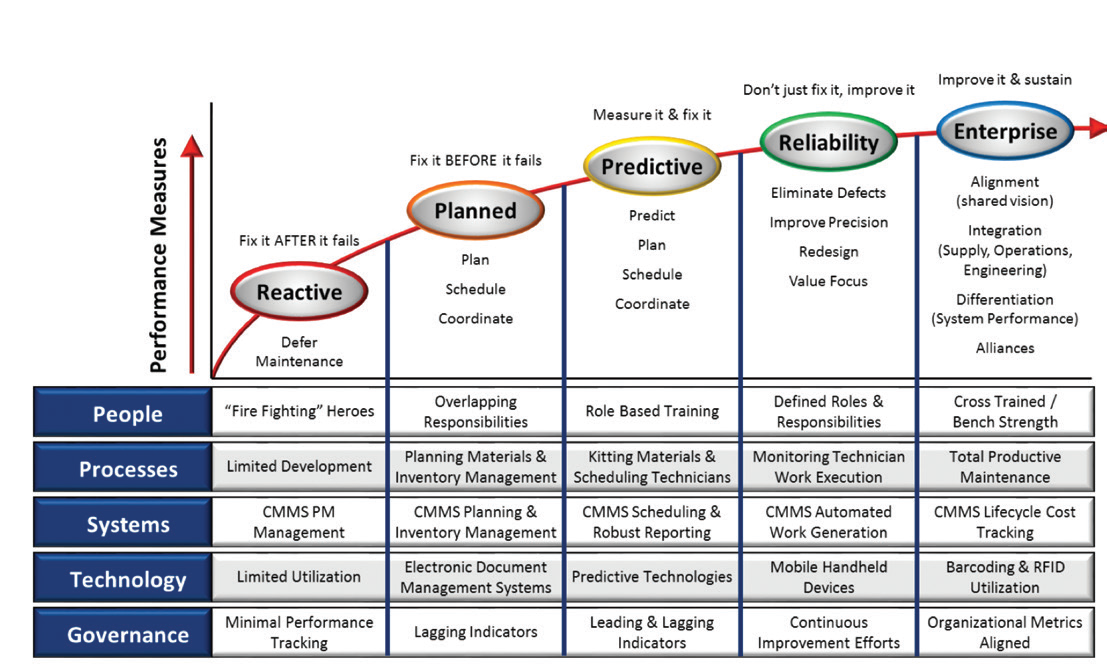

As an engineer, I have always prided myself on being able to fix things and “keep the plant running.” In my earlier days, I thought it was fantastic to get the recognition I did for fixing things. I never considered it to be reactive. Heck, I did not even know what that meant. With the advancements in today’s technology and improvements to Enterprise Asset Management (EAM) systems and Computerized Maintenance Management Systems (CMMS), if we deploy them properly and in line with best practices, it is possible to reach previously unreachable levels of efficiency, data quality, and meaningful reports. If your organization is in a reactive state of maintenance (see the Maintenance Maturity Continuum below), all the things that need to be done to fix and repair assets need to be documented in the form of a job plan so that it can be used the next time that work needs to be done. Accurate and complete job plans enable planners to be more efficient at what they do. If your organization is in a predictive or reliability-based state of maintenance, congratulate yourselves and read on, as you may discover new areas of opportunity.

Unfortunately, many organizations still do not have fully developed and implemented planning and scheduling programs. Work still gets done, but at what cost to the organization? Without a properly developed and defined planning and scheduling function, maintenance inherently operates in a more reactive mode. Why? Without proper planning and scheduling, work quality, equipment/asset uptime, and maintenance productivity will not be at their maximum levels. This is due to excessive non-value time added during the job and between jobs. Additionally, planners are not able to effectively plan for the number of technicians that are assigned to them. Overall maintenance costs also increase due to the acquisition and storage of unnecessary spare parts, and up to 10% of the energy being consumed is wasted by poorly maintained equipment.

Benefits of Planning & Scheduling

Instead of talking about what proper planning and scheduling is, I would like to set the stage for why you want proper planning and scheduling as a key initiative within your organization. Let’s consider several areas where waste occurs and what this waste could mean for an organization. Without planning and scheduling, the wrench-on time for a company is on average only 35%. That means that for every technician working an 8-hour day, only 2.8 hours of actual work on assets is done. Of the remaining 65% of the time, the breakdown is as follows:

- 5% goes towards receiving instructions

- 12% goes towards obtaining tools and materials

- 15% goes towards travel time to and from the job

- 8% goes towards coordination delays

- 5% goes towards idleness at the job site

- 5% goes towards late starts and early quits

- 10% goes towards authorized breaks

- 5% goes towards excess personal time

With the addition of proper maintenance planning and scheduling, a company is able to increase the wrench-on time from 35% to 65%. At this level of efficiency, a technician working an 8-hour day will complete 5.2 hours of actual work. With 65% of the engineer’s time being used efficiently, only 35% of their time is wasted.

At this point, you might be asking yourself: “So what? Why should I invest time and effort in establishing a proper planning and scheduling function?” The simplest answer would be because it will allow your facility to move away from a reactive state of maintenance and improve overall work force efficiency.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.