Introduction

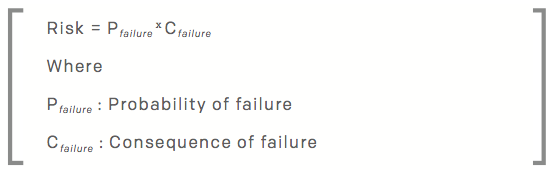

Ensuring the integrity of process piping systems in the Oil & Gas industry (specifically those related to the ASME Code B31.3) is a key issue with respect to the process, business, safety, and the environment. However, in the current cost reduction environment, some companies are adopting a very risky strategy for piping systems where maintenance and inspection tasks are reduced and eliminated indiscriminately, without considering the relative importance of piping for the process. Other Oil & Gas facilities have not implemented an inspection program for pipework due to their asset integrity management program just being focused on pressure vessels, heat exchangers, and fired heaters. Even though the potential consequence of failure of a piping system is typically less than the consequence of failure of a pressure vessel (from a risk-based inspection perspective), a process piping system failure could have a strong impact on the business due to interruptions in production, and a catastrophic effect if an explosion or fire occurs or a hazardous chemical is released. In fact, the probability of failure of a pipe is greater than that of a pressure vessel. The Health Safety Executive Report RR672 "Offshore Hydrocarbon Release 2001-2008" revealed that piping is the most common equipment type to experience releases, and the most frequent equipment failure cause is mechanical failure, then mechanical fatigue. This is due to the fact that piping systems are subjected to vibration and mechanical and thermal fatigue loads that generate constant movement on the system. Moreover, most process piping is not piggable and sometimes the access for inspection is not an easy task when compared to pressure vessels.

This article presents a methodology to assess piping system criticality in order to help inspection and maintenance managers make the right decisions when developing and managing inspection and maintenance plans. Moreover, this methodology can help managers do this in a cost-effective way, without compromising the asset’s safety and mechanical integrity performance.

Criticality Assessment Methodology

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.