| Date | March/April 2013 |

| Volume | 19 |

| Issue | 2 |

| Return to Journal Index | |

March/April 2013 Inspectioneering Journal Article Index

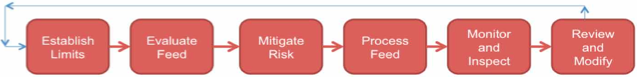

Over the past few years increased feedstock flexibility has become a growing reality for sustainability of the refining business, requiring processing of more difficult crudes, increased volumes of spot cargoes, and rapid response to crude...

For crude oil refiners and traders, information is the lifeblood of their operations and business decisions. The information obtained by crude oil assays, which includes physical properties and compositional analysis of a crude oil, provides...

If an operator finds cracking in a furnace waste heat boiler, excessive thinning in an absorption tower, or severe bulging in a converter, FFS assessments—not standard code analyses—are needed to evaluate the unit’s mechanical...

Pinnacle's data-driven reliability framework ensures the right data is fueling the right intelligence, helping you make confident, strategic decisions.

A pattern of requests for key performance indicators (KPIs) related to equipment integrity management (IM) programs has appeared on Inspectioneering’s LinkedIn group discussion as well as other industry forums. Furthermore, the topic came up...

This is the first in a series of three articles that will introduce Electro Magnetic Acoustic Transducer (EMAT) and its practical applications in the field of nondestructive testing (NDT). EMAT, or Electro Magnetic Acoustic Transducer, is an...

Steam reformers are critical assets to many refining and chemical manufacturing plants and facilities, and it is well known that the reformer is one of the most challenging assets to maintain and operate. Common problems in reformer operations...

It is another day at the plant and as usual, your boss calls and says there is a meeting in the conference room that he wants you to attend regarding a compressor failure. That is all you know, but from experience you know it must be something major...

Sulfidic corrosion of piping and equipment within the refining industry continues to be a significant cause of leaks and issues that can lead to early replacements, unplanned outages, and incidents potentially resulting in loss of property and...