Now, more than ever, pipeline owners and operators are under intense scrutiny to ensure safe and dependable pipeline systems. The increased pressure comes from several fronts; upstream operators’ need to move valuable production to hydrocarbon processors, refiners’ and petrochemical companies’ need to move products to market; and legislators’ and community stakeholders’ need to ensure public safety. Yet, with the current wealth of new oil and gas reserves found in shale plays in the U.S. and around the world, pipeline operators are driven to expand current systems and build out new facilities; so getting it right the first time is essential to their business success.

As savvy pipeline operators know, ensuring safe and dependable operations can only be accomplished with a robust Pipeline Integrity Management (PIM) program. PIM programs determine proper assessment methods, identify risks and threats, manage testing, structure repairs, manage mitigations and remediation if necessary, and streamline documentation and reporting tasks. The ultimate goal is to safely operate the pipeline system—i.e., keep the product in the pipe. All of the various steps included in PIM rely on having access to the proper data. Data drives PIM, and PIM is continuous, so ensuring correct data is paramount and never ending. Pipeline operators need to be able to identify when any pipeline component was originally installed, inspected, and maintained, as well as where and how it was manufactured, tested, received, and stored before its installation. Furthermore, operators need to be able to validate pipeline data, such as maximum allowable operating pressure (MAOP) records. They must also be able to identify and trace any material, from a documentation standpoint, from design through abandonment of the pipeline asset. It is this pipeline data that must be identified, validated, and utilized to fuel the PIM lifecycle, which is performed to maximize and maintain a pipeline’s integrity for its duration.

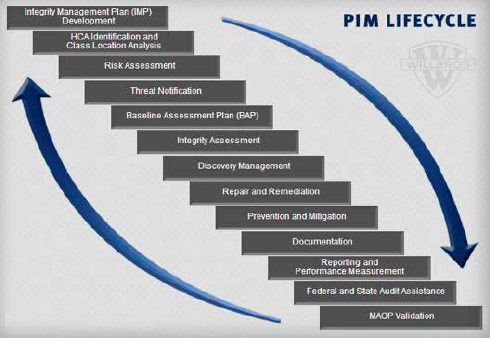

PIM Steps

The Willbros PIM lifecycle is made up of 13 separate, yet intertwined areas of integrity; all of which are continually monitored and reevaluated. These areas are identified in the U.S. Department of Transportation’s (DOT) Title 49, CFR Part 192 for natural and other gas, and CFR Part 195 for hazardous liquids. Below is a diagram which depicts the components of the pipeline integrity life cycle. It is important to note a key difference between Parts 192 and 195, which is that liquid operators are not required to determine class location. The diagram shows this as one of the steps, and class location is only applicable to natural and other gas integrity management. In fact, while both codes indicate integrity management is only applicable within high consequence areas, many companies are expanding the use to their entire pipeline system in an effort to exceed the federal requirements.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.