| This article is part 3 of a 3-part series. |

| Part 1 | Part 2 | Part 3 |

In two previous issues we discussed the important difference between steady and cyclic loading, and why loose bolts fail while tight ones do not. This issue will offer two suggestions for reducing the tendency for bolts to become loose.

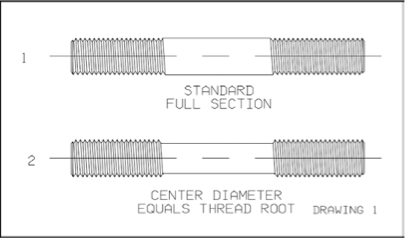

The first deals with the rigidity of a bolt and its stress concentration factor. Figure 1 shows two typical flange stud bolts, each being of equal strength for steady loading, but the one with reduced mid section being stronger for cyclic loading.

The effective load bearing cross section for a bolt is the root diameter of the threaded area. The second bolt has the same effective cross section as the first, even though the center portion has been machined down to the root diameter. So, for steady loading, the two bolts are essentially the same.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.