In the oil and gas industry, pressure vessel integrity is a major concern. After internal and external inspections various anomalies or defects can be reported and repairs could be required for pressure vessels in order to restore its original condition. The first question for engineers, operators and managers is, can we keep operating at this pressure level? Is it safe? Or do I have to take it out of service to repair? Structural integrity assessment methodologies can be used to determine the suitability of a vessel for service as well as a good maintenance management can reduce the inspection cost and extend the equipment life within safe, reliable limits. Pressurized equipment such as this large horizontal vessel in a typical gas plant can experience in-service damage.

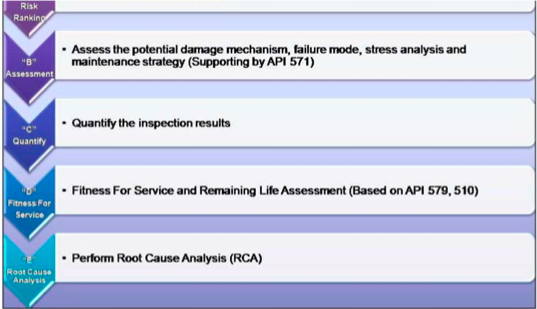

The vessel condition can deteriorate due to various factors including mechanical problems, process related problems and corrosion problems. This strategy includes fitness-for-service and remaining useful life analyses of a large vessel based on the non-destructive examination results, mechanical properties and operating conditions. The analysis procedure, stress analysis and remaining useful life evaluation for the vessel are discussed. Recommendations for consideration of anomalies detected during the assessment are also presented. The assessment methodology employed in this paper can be applied to other similar pressurized vessels in Oil & Gas, chemical and petrochemical plants. The methodology applied by ABB Service in a NGL gas plant aims to maximize the pressure vessel reliability and availability. The procedure intends to determine its mechanical behavior under different process conditions, to identifythe potential damage mechanisms and get accurate results from non destructive inspections for the analyses. The methodology used in this analysis consists of five steps, Step “A”: Perform a qualitative risk analysis using an output risk matrix to select equipment that requires a more detailed analysis; Step “B”: Perform the analysis of equipment (stress analysis, potential damage mechanism, failure mode, process condition and maintenance strategy); Step “C”: Quantification of inspection results; Step”D”: Fitness for Service Analysis; Step “E”: Failure Analysis. A key factor of the analysis is to complete every step in sequence from A to E (see figure 1).

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.