Introduction

After pressure equipment (aka fixed or static equipment) is designed, fabricated, and constructed to new construction codes and standards (C/S), it is placed in-service, at which time the API In-service Inspection (ISI) C/S and ASME Post-Construction C/S begin to govern. Within the API Standards Organization, the Subcommittee on Inspection (SCI) produces and maintains most of the ISI standards that govern in the refining and chemical process industry. Also within the API, the Corrosion and Materials Subcommittee (CMSC) produced many recommended practices that are referenced in the ISI C/S. Within the ASME, the Post Construction Committee (PCC) produces and maintains most of the post construction (means the same as ISI) standards that govern equipment after it has been placed in-service.

This article shows how many of those ISI C/S are intended to work together to maintain the safety and reliability of in-service pressure equipment and piping. An important note for each reader of this article is to be cognizant of using the latest edition of each of the referenced ISI C/S. Both the API and ASME use the rigorous, standardized consensus building process outlined by the American National Standards Institute (ANSI) for formulating and publishing their respective C/S. Because of active ISI standardization programs within both societies, the latest editions of the referenced ISI C/S have some important revisions and additions that make each of the referenced ISI C/S better and more useful for the owner-user. So it’s very important that each reader have access to the latest edition of each of the referenced ISI C/S at the end of this article.

Inspection Planning

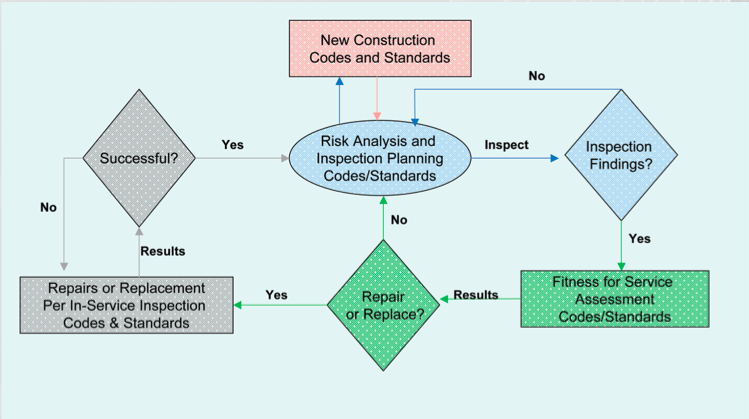

Figure 1 (15) is a simplified block diagram that shows the process for managing pressure equipment with in-service inspection (post-construction) codes and standards. As you can see, the first step after being placed in-service is the oval labeled “Risk Analysis and Inspection Planning Codes and Standards”. At this point the process begins to determine what the ISI strategy needs to be for optimum safety and reliability of the in-service pressure equipment. Within the API, this process starts with API-510 (1) and API- 570 (2) for inspection planning and execution for pressure vessels and piping respectively. These two codes provide a comprehensive plan for the in-service inspection, repair, rating, and alteration of pressure vessels and piping. But they are not stand-alone documents. Each of these codes contains references to many other ISI C/S that provide additional valuable information that will assist the owner- user in determining the optimum ISI strategy.

Since risk analysis is now a predominate part of inspection planning in the oil and chemical industry, both API RP 580 (3) and API RP 581 (4) are referenced in both the API 510 & 570 Codes for inspection planning. API RP 580 1st edition is currently being extensively revised and updated for the 2nd edition. The ANSI/API ballot resolution process is expected to be completed in the spring of 2009 at the API Refining Standards Meeting, with publication of the 2nd edition of API RP 580 expected near year-end 2009. This recommended practice covers all the appropriate steps for any and all RBI processes and software to follow that expect to produce quality inspection planning based on risk analysis.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.