| This article is part 2 of a 2-part series. |

| Part 1 | Part 2 |

Part 1 in this 2 parts series laid the technical foundation for the methodology and technology. Part 2 will now demonstrate both through actual applications.

Case Study 1- Tunnel Port Effect

Correct sizing of tunnels and ports is essential to balance fluegas flows within the box.

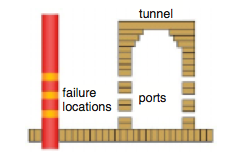

Fluegas maldistribution will contribute to the variation in tube temperatures and lead to reduced furnace efficiency and limited firing rates. Also, in some circumstances, poor design of the tunnels and ports can have a much more dramatic effect; it can lead to premature tube failure. The failure is caused by localised creep damage at the bottom of the tubes and is shown schematically in Figure 6. The area of damage is typically 100 to 150 mm (4 to 6 inches) long, with the tube above and below the failure showing no damage.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.