Editor's Note: This article is the second part in a series on Microwave NDT. To read the first article, click here.

Once the effectiveness of the microwave NDE technique was firmly established for polyethylene and fiberglass piping and piping components, other types of materials were collected and inspected to determine the range for which the technique could prove useful. It was soon discovered that this technique has broad ranging capabilities that cover essentially any bulk dielectric material. Coupons were either prepared locally or sent in from different manufacturers, both national and international, to determine the effectiveness of the technique for specific applications.

As noted in previous articles, examination techniques have been developed that further enhance the results obtained using the microwave NDE method. In many cases, the technique provides startlingly clear images of defects in materials for which no previous inspection technique existed.

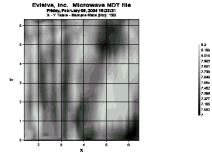

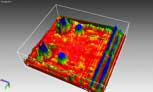

The figures included in this article provide visual evidence of the effectiveness of the microwave NDE technique. Note the clarity of the internal defects and structures of interest apparent in all of the scans.

Figures 1 and 2 show a plywood panel with no known defects. Figure 1 is a photo of the plywood panel and Figure 2 shows the microwave scan of the panel. The scan clearly shows wood grain features both on and beneath the surface of the wood.

Figure 3 shows a honeycomb fiberglass panel coupon with intentionally embedded defects. The defects are disbonds at the substrate, potted disbonds are at the far left, the potted cores in the center, and the splice joint at the right of the image. None of the defects were visible at the surface of the coupon.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.