| This article is part 2 of a 3-part series. |

| Part 1 | Part 2 | Part 3 |

Last issue, in keeping with the evaluation that "gussets are stiffeners, not strengtheners", we discussed welding around the ends of the gusset plate instead of just along the sides in order to reduce the stress concentration. A further improvement in the gusset life can be obtained by welding it to a reinforcing plate and/or a fitting instead of directly to the pipe.

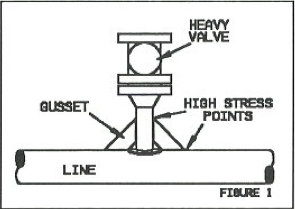

One common situation is shown in Figure 1. Because of the pendulum action of the heavy valve under vibration, high stresses are encountered at the ends of the gussets, as shown. Even though the life of the joint has been improved by continuing the full strength weld around the ends, cracks in the pipe can still be encountered.

In Figure 2, the reinforcing plate around the nozzle has been enlarged so that the gusset is attached to it, instead of the line. At the other end, it is welded to a valve flange. It is important to position the gussets so that they do not interfere with fitting a wrench over the flange blots for assembly and disassembly.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.