The United States Department of Labor (USDOL) Occupational Safety and Health Administration (OSHA) standard 29 CFR 1910.119, "Process Safety Management of Highly Hazardous Chemicals," has been in effect since May of 1992. To enforce this standard, OSHA has targeted seven industries for which it plans and conducts routine compliance inspections; additionally, OSHA conducts inspections in response to complaints, referrals, and facility accidents. This article will discuss how well those inspected facilities fared in achieving compliance with the standard - and with the Mechanical Integrity element (1910.119 (j)) in particular.

During the course of its inspections, OSHA cites (and fines) companies for specific weakness in their Process Safety Management (PSM) programs. A comprehensive listing of these citations is available from OSHA's Office of Management Data Systems. Based on the data from May of 1992 through February of 1995, we have compiled statistics regarding the citations.

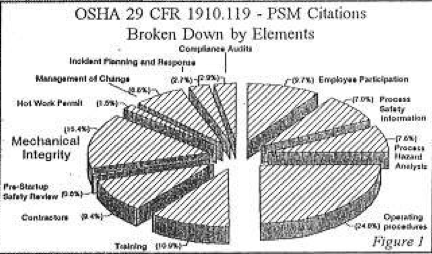

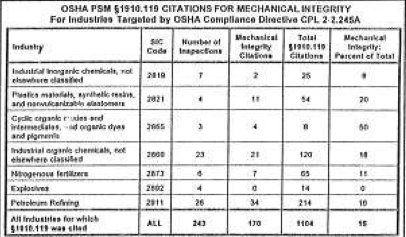

The data shows, that OSHA has found Mechanical Integrity to be a major weakness in facilities' PSM programs; in fact, of the fourteen elements of the standard, only Operating Procedures (1910.119 (f)) resulted in more citations than did Mechanical Integrity. Figure 1 illustrates the breakdown of the citations by element while Figure 2 shows the number of citations given to those industries targeted by OSHA for routine inspections.

A closer examination of the data shows exactly why OSHA cites companies for the mechanical integrity element of their programs. In the majority of cases, citations were issued not because the process equipment was deficient or defective, but because methods of verifying and documenting mechanical integrity were insufficient. Of the six sections of 1910.119 (j), 41% of the citations were for Written Procedures (1910.119(j)(2)) and 30% were for Inspection and Testing (190.119(j)(4)).

The Written Procedures section of the standard requires that the "employer shall establish and implement written procedures to maintain the ongoing integrity of process equipment." Examining the text of the actual citations (which OSHA makes available to the public) illustrates exactly how the written procedures have been deficient. Some companies were cited because they simply had no written procedures; however, others did have written procedures in place, but OSHA inspectors deemed them incomplete. For example, in many cases the documentation did not specify which individuals were responsible for given procedures, in other cases the procedures did not cover all the equipment being used. In addition, many facilities presumably had thoroughly adequate written procedures, but OSHA determined that the procedures were not fully implemented. In some cases, deficiencies were more complicated. For example, one facility's written procedures referenced (and relied upon) manufacturers' equipment manuals, but "did not identify who to access such manuals or information between 5:00 pm and 5:00 am when the new maintenance office is generally locked". Clearly, OSHA inspectors can be quite strict in their interpretation of the regulations.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.