Del Underwood: About the Author

Det Norske Veritas

Is this you? Please help us keep this page up-to-date by occasionally submitting your updated information.

Published Articles

In two previous issues we discussed the important difference between steady and cyclic loading, and why loose bolts fail while tight ones do not. This issue will offer two suggestions for reducing the tendency for bolts to become loose.

In the previous issue we dealt with the fact that bolts can withstand significantly less cyclic loading than steady loading. We are now looking at the mechanics of why bolts fail if flanges are allowed to separate during operation.

A continually frustrating phenomenon to many of us is the situation where a tight bolt will function satisfactorily, but in the same situation, a loose bolt will fail...

In two previous issues we discussed the important difference between steady and cyclic loading, and why loose bolts fail while tight ones do not. This issue will offer two suggestions for reducing the tendency for bolts to become loose.

In the previous issue, we dealt with the fact that bolts can withstand significantly less cyclic loading then steady loading. We are now looking at the mechanics of why bolts fail if flanges are allowed to separate during operation.

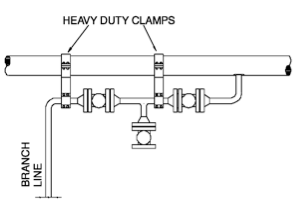

In a past issue, we discussed one solution to the instrument line block valve pendulum problem. This was where the valve assembly can be mounted remotely from the vibrating product line, such as at-grade. This issue covers two possibilities where the valves need to remain close to the vibrating line.

In a past issue, we discussed one solution to the instrument line block valve pendulum problem. This was where the valve assembly can be mounted remotely from the vibrating product line, such as at-grade. This issue covers two possibilities where the valves need to remain close to the vibrating line.

Continuing with the theme "a billiard ball on the end of a fly rod," this month we will look at one alternative to mounting a heavy block valve on a small diameter nipple in vibrating conditions. A popular situation is where the purpose of the...

There are a number of terms to describe commonly experienced problem conditions with reciprocating compressors. One of the terms that I have always appreciated is the pendulum action of a large unsupported mass on the end of a vibrating pipe.

This final issue on gusset problems will discuss why gussets are "stiffeners" rather than "strengtheners." The effective load bearing capacity of a member of given strength is based upon how large a cross-sectional area is carrying the load. Gussets are commonly welded to tubular members to reduce their flexure under a bending load.

Last issue, in keeping with the evaluation that "gussets are stiffeners, not strengtheners," we discussed welding around the ends of the gusset plate instead of just along the sides in order to reduce the stress concentration. A further improvement in the gusset life can be obtained by welding it to a reinforcing plate and/or a fitting instead of directly to the pipe.

A key to any piping evaluation program is to understand where problems can occur. Vibrating piping can propagate a crack relatively quickly. Have you ever installed gussets to stabilize a vibrating pipe situation only to find, shortly thereafter, that the gussets have cracked the pipe? If so, you've got lots of company.