Introduction

Power Boilers offer challenges for most facilities' Inspection and Engineering departments. BP's Whiting Refinery has five 400,000 lbs/hour steam generating boilers built in 1948 that supply the refinery's steam needs as well as 75% of its electrical demand. During recent internal inspections on these boilers, unique damage mechanisms were observed, such as stress assisted corrosion and dissolved oxygen pitting. This resulted in the use of some specialized nondestructive testing (NDT) techniques, metallurgical analysis, and finite element analysis (FEA) in order to complete fitness for service (FFS) evaluations for the boilers and allow continued safe and reliable operations. The maintenance and water treatment history of these boilers will be discussed in this article, as well as how this may have played a role in the damage observed.

Maintaining mechanical integrity for aging power boilers can be challenging. This article provides a case study on how mitigating one damage mechanism led to the discovery of another, and how refinery engineers collaborated with industry experts to fully understand an unfamiliar damage mechanism and perform a fitness for service assessment for the safe and reliable operation of power boilers.

1948 Dual Circulation Foster-Wheeler Boilers

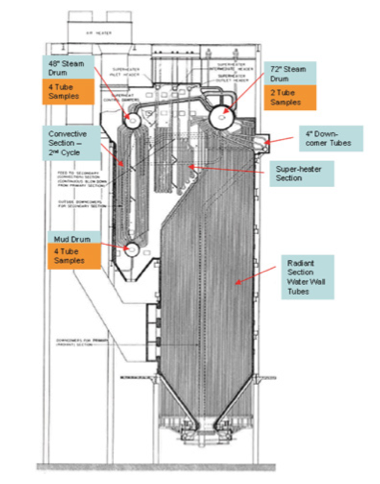

The five boilers at the Whiting Refinery are dual circulation Foster-Wheeler boilers, commissioned in 1948. Each boiler is a bent-tube type dual circulation boiler designed for a maximum continuous output of 400,000 lbs steam/hr at 1350 psig at the super-heater outlet. In 1982 the super-heater section was modified to increase this capacity to the current design of 450,000 lbs. steam/hr. The steam temperature at the super-heater outlet is 900°F. This dual circulation, three drum unit contains two separate heat absorbing sections, each with its own separate circulation system. All tubes in the boilers are SA-192 carbon steel material and rolled, not welded into their respective drums.

The convective section consists of 720 2½" O.D. 0.24" (4 GA) thick tubes rolled into both the mud drum and 48" steam drums. The radiant section or “water wall tubes” consist of 243 3" O.D. 0.26" (3 GA) thick tubes rolled into the 72" steam drum. Additionally, there are 45 4" O.D. 0.34" (0 GA) wall water down-comer tubes rolled into the 72” steam drum. Figure 1 shows a general arrangement drawing for the Foster-Wheeler boiler. It also shows the locations where tube samples were taken as discussed later in the article.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.