| This article is part 7 of a 10-part series. |

| Part 1 | Part 2 | Part 3 | Part 4 | Part 5 |

| Part 6 | Part 7 | Part 8 | Part 9 | Part 10 |

Introduction

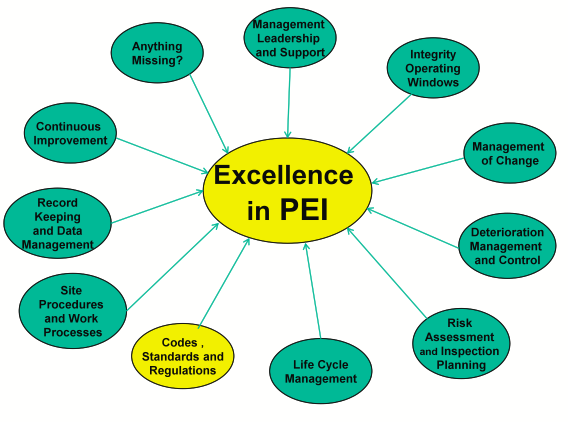

In the first article in this series entitled How to Put It All Together - Guide to Organizing a Successful PEI Program, (1) I provided an overview of the necessary Management Systems (MS) for a successful program to achieve excellence in pressure equipment integrity (PEI). This is the seventh article in that series. Clearly, Codes and Standards (C/S) have a major role in achieving excellence in Pressure Equipment Integrity and Reliability (PEI&R). This article will show how Industry PEI Codes and Standards have a very important role in achieving excellence in PEI&R, but will also mention the impact of PEI regulations. And finally I will show how the management system (MS) for PEI Codes, Standards and Regulations needs to be integrated with the 9 other important management systems shown in figure 1 in order to achieve excellence in PEI&R.

For purposes of review and for those who did not see or perhaps remember the original article in the Sept/Oct, 2009 edition of the Inspectioneering Journal (IJ), and in order to set the stage for this follow-on article on PEI C/S, I will repeat directly below, some of the same introduction included in the first article(1). The second article in the series covered Management Leadership and Support for PEI (4), and appeared in the Jan/Feb, 2010 edition of the IJ. The third article in the series covered Management of Change and Integrity Operating Windows for PEI (5), and appeared in the Mar/Apr, 2010 edition of the IJ. The fourth article in the series covered The Role of Corrosion Control in Achieving Excellence in Pressure Equipment Integrity and Reliability (6) and appeared in the May/June, 2010 edition of the IJ. The fifth article in the series covered The Role of Risk Assessment and Inspection Planning in Pressure Equipment Integrity and Reliability(7) appeared in the Sept/Oct, 2010 edition of the IJ. The sixth article in the series covered The Role of Life Cycle Management in Achieving Pressure Equipment Integrity and Reliability (8) and appeared in the Jan/Feb, 2011 edition of the IJ. For those who would rather not review the introductory material, you can skip directly to the third section of this article which is labeled PEI Codes, Standards and Regulations.

Knowing what all needs to be accomplished in order to achieve excellence in PEI&R is one thing, but knowing how to organize it all for success is quite another. I have previously written/published numerous articles about what all needs to be accomplished (1-3). In this article I will show how to organize all 10 of the PEI&R Management Systems (MSs) to achieve overall success i.e. in order to make sure that everything that needs to be accomplished, is accomplished using PEI&R management systems (MS) and work process (WP) descriptions. Without an effective organizational strategy for PEI&R, many of the 101 essential elements of PEI&R(2) can “drop between the chairs” because there may be no management system in place to make sure that each element gets properly planned, scheduled and completed at appropriate intervals by a responsible party. However with an effective PEI&R MS in place, each site should be able to maintain pressure equipment integrity (i.e. no breaches of containment) and to achieve pressure equipment reliability (i.e. having pressure equipment available to function as designed to meet the business plan), both of which comprise PEI&R excellence.

Speaking of excellence, Vince Lombardi, one of the most famous football coaches in the history of the NFL, once said, “Perfection is not attainable, but if you chase perfection, you will catch excellence.” I believe that to be very true and especially when it comes to implementing an effective pressure equipment integrity program. But what is excellence in PEI&R? It’s not “gold plating” nor overdoing nor spending too much on the PEI&R program. It’s simply doing everything that needs to be done, doing it right, doing it when it needs to be done, in order to create, implement and sustain the PEI&R program to avoid breaches of containment. Keep that definition in mind, as I will refer to it often. Having effective management systems (MS) in place for all the PEI&R issues that need to be handled is the foundation for a successful PEI&R program.

But what is a management system (MS)? In my experience, it’s simply a compendium of all the necessary information that describes what must be done, why it needs to done, how it is to be done, and how often or when. Some operating sites then combine their PEI&R MS with PEI&R work process (WP) maps and descriptions to show who is involved and how the work flows, i.e. what comes first, next, last and in between plus what can be done in parallel and what must be done in series. Management systems are the input to the WP maps and descriptions. For the purpose of this article, I will concentrate on creating, implementing and sustaining the MS, but will mention how WP maps and descriptions are also needed to achieve efficiency and effectiveness in the PEI&R program.

Note: For those of you who are more used to the term “mechanical integrity (MI)”, I use PEI&R throughout this article as somewhat of the equivalent of MI, but pertaining only to what I refer to as pressure equipment or what some others may refer to as “fixed equipment” or “stationary equipment”.

I recognize that there may be many ways to organize a PEI&R MS program for success, so I will present just one suggested way to do it, not the only way. Other ways to organize a PEI&R MS program may be equally effective, just as long as all necessary elements are included, scheduled and accomplished according to plan. This article is intended for those organizations that may not yet be achieving excellence in PEI&R (see above definition) and that believe perhaps the way they are organized (or even disorganized) may be part of the problem. Without effective PEI&R MSs, even if we know what needs to be done, we might be just “flailing at the wind”, as my grandmother used to say, rather than accomplishing what needs to be done effectively and efficiently to prevent beaches of containment.

The Ten PEI&R Management Systems

The way I see it, there are 10 essential MSs needed for an effective PEI&R program that can achieve excellence. I like to think of having all 10 of the necessary MSs for PEI&R in two filing cabinets, with 5 drawers each, i.e. 10 drawers total. Now before I lose half my readers right off the top who don’t put anything into those ancient metal cabinets any more, bear with me, as I’m old enough to still think that way, even though I well know we keep all our files nowadays stored electronically. Back on track; each of my filing cabinet drawers has one of 10 PEI&R MSs that contain all the necessary information that describe what needs to be accomplished, and how to accomplish it, in order to achieve success in PEI&R. So in my two PEI&R MS filing cabinets, I have one of these PEI&R MS labels on each of the 10 MS drawers:

- Management Leadership and Support for PEI&R

- Integrity Operating Windows(IOW)

- Management of Change(MOC)

- Deterioration Management and Control(CM&C)

- Risk Assessment and Inspection Planning(RA&IP)

- Life Cycle Management(LCM)

- PEI&R Codes and Standards(C/S)

- Site Procedures and Work Processes for PEI&R

- PEI&R Record Keeping and Data Management (RK & DM)

- Continuous Improvement (CI) for PEI&R

Into each of these drawers, I will have multiple folders where I file all the procedures, standards, guidelines, work processes, best practices, engineering evaluations, failure analyses, metrics, etc. that I need in order to outline and operate a successful PEI&R program. For those who are more visually oriented learners like me, those 10 PEI&R MS are shown schematically in figure 1.

As you can see from the list of 10 PEI&R MSs above and in Figure 1, there is much more to a robust PEI&R program than just inspection planning, inspection execution, data taking and data management. PEI&R is not just the result of a competent inspection program! It takes an effective multi-disciplined approach with management, operations, engineering, technology, maintenance and inspection to accomplish what needs to be done to achieve excellence in PEI&R. All of these PEI&R MSs need to be highly integrated with each other in order to achieve success in PEI&R. Hence, if I were to draw figure 1 more accurately, there would be a double-ended arrow from each MS bubble to every other MS bubble on the diagram. But that would be too messy and the effect of the illustration would be lost; so you will just need to be aware that all those other arrows exist, even though they are not shown. Those operating sites, which still have each of their functions mostly “working in silos” and not effectively integrated with the other disciplines (sub-optimized), will not be able to achieve the level of PEI&R success that is vital in today’s competitive environment in the energy and petrochemical industry that demands the utmost in cost containment and reliability.

PEI Codes, Standards and Regulations

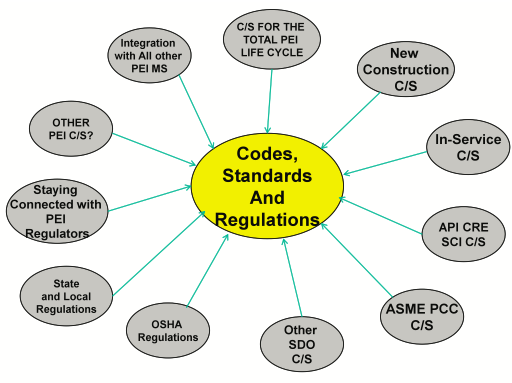

With the completion of the six previous articles in this series, we have moved clockwise around the chart in figure 1 to about the 7 o’clock position to PEI Codes, Standards (C/S) and Regulations. In figure 2 is the bubble chart for PEI C/S. For purposes of this article I will use the acronym (C/S) generically to apply to a wide variety of names for the various documents published by Standards Development Organizations (SDO’s) that include not only those officially named “codes or standards”, but also those other documents that may be called recommended practices, best practices, bulletins, specifications, guidelines, publications, etc.

As many of you know, I’ve spent the last 35 years of my PEI career heavily involved in the industry codes and standards committees, so this article comes from long experience with industry PEI C/S. I could write a book on the application of PEI Codes and Standards in the petroleum industry, but I will refrain from doing so for this short article and just provide a few overview highlights about the importance of them. I have personally benefited immensely in my PEI knowledge and skills by my long standing participation in those industry C/S committees (especially API & ASME), and I encourage readers who have a passion for excellence in the PEI discipline to do the same. The success of the API & ASME PEI committees in putting together “Recognized and Generally Accepted Good Engineering Practices” (RAGAGEP) is dependent upon knowledgeable PEI specialists participating in the American National Standards Institute (ANSI) consensus process applied by most SDO’s to continuously create and update our industry PEI C/S.

After retirement from Shell, I have worked for many other clients in the refining and chemical industry. As such, I’m amazed at how many of them don’t know about and/or don’t use some of the industry PEI C/S to the maximum extent possible; and that many are not working from the latest editions of those PEI C/S. These industry PEI C/S contain a world of expert knowledge and best practices built up over many years by PEI specialists and consultants from many different companies. The price of most of these C/S is small compared to the value of the knowledge contained in them and compared to the cost avoidance of applying them to the fullest extent possible to avoid PEI incidents at each operating site. Before any new editions of these PEI C/S are published, they go through a rigorous consensus building ANSI standardization process where all members of each committee or task group in charge of a particular standard thoroughly discuss each issue, draft it into standardization terminology, vote on it and finally come to consensus on the “best practices” before anything is published. This standardization process is tedious and lengthy, but ensures the end user that the contents of every standard are fully vetted before publication and that the contents really do represent RAGAGEP for our industry. New and updated technologies, methodologies, and work practices are constantly being reviewed for inclusion in these PEI standards; so the user that is still using outdated editions is not getting the full value of the latest information and work practices in each of the C/S. Now let’s go around the bubble chart clockwise in figure 2 to briefly summarize the major areas where PEI Codes and Standards should be contributing to PEI&R excellence at each operating site.

Codes and Standards for the Total PEI Life Cycle

At the 12 o’clock position on the C/S MS bubble chart in figure 2, we start with summarizing all the ANSI C/S and other SDO documents that apply to the life cycle of pressure equipment. The nine stages of PEI covered in the total life cycle of pressure equipment include: design, procurement, construction, installation, commissioning, operation, inspection, maintenance and finally decommissioning.

The ASME Post Construction Committee (PCC) has published The Guide for Life Cycle Management of Pressure Equipment Integrity (ASME PTB-2-2009(9)) which summarizes all the codes, standards, recommended practices, specifications and guidelines that can be used by manufacturers, owners, users, regulators, engineers and all other stakeholders in the total life cycle management (LCM) of pressure equipment. As most of you know, there is a very wide array of such documents available and to the best of my knowledge up until now, there has been no comprehensive guide to how all these documents can be tied together in the cradle to grave management of pressure equipment, from concept to decommissioning. ASME PTB-2-2009 fills that void.

The scope of the document for the initial publication primarily covers those documents produced by ANSI accredited Standards Development Organizations (SDO’s) like ASME, API, NB, NACE, ASNT, ASTM, TEMA, ASCE, EPRI, etc. However, it also covers some useful and applicable technical papers, other publications and references like WRC Bulletins that offer good advice in the LCM of pressure equipment.

Comments and Discussion

There are no comments yet.

Add a Comment

Please log in or register to participate in comments and discussions.